Institute of Mechanics,

Chinese Academy of Sciences

2018 Vol.8(1)

column

Display Mode: |

Theoretical and Applied Mechanics Letters 2018, 8(1): i-iii.

Abstract:

Theoretical and Applied Mechanics Letters 2018, 8(1): 1-2.

doi: 10.1016/j.taml.2018.01.005

Abstract:

Theoretical and Applied Mechanics Letters 2018, 8(1): 3-6.

doi: 10.1016/j.taml.2017.09.007

Abstract:

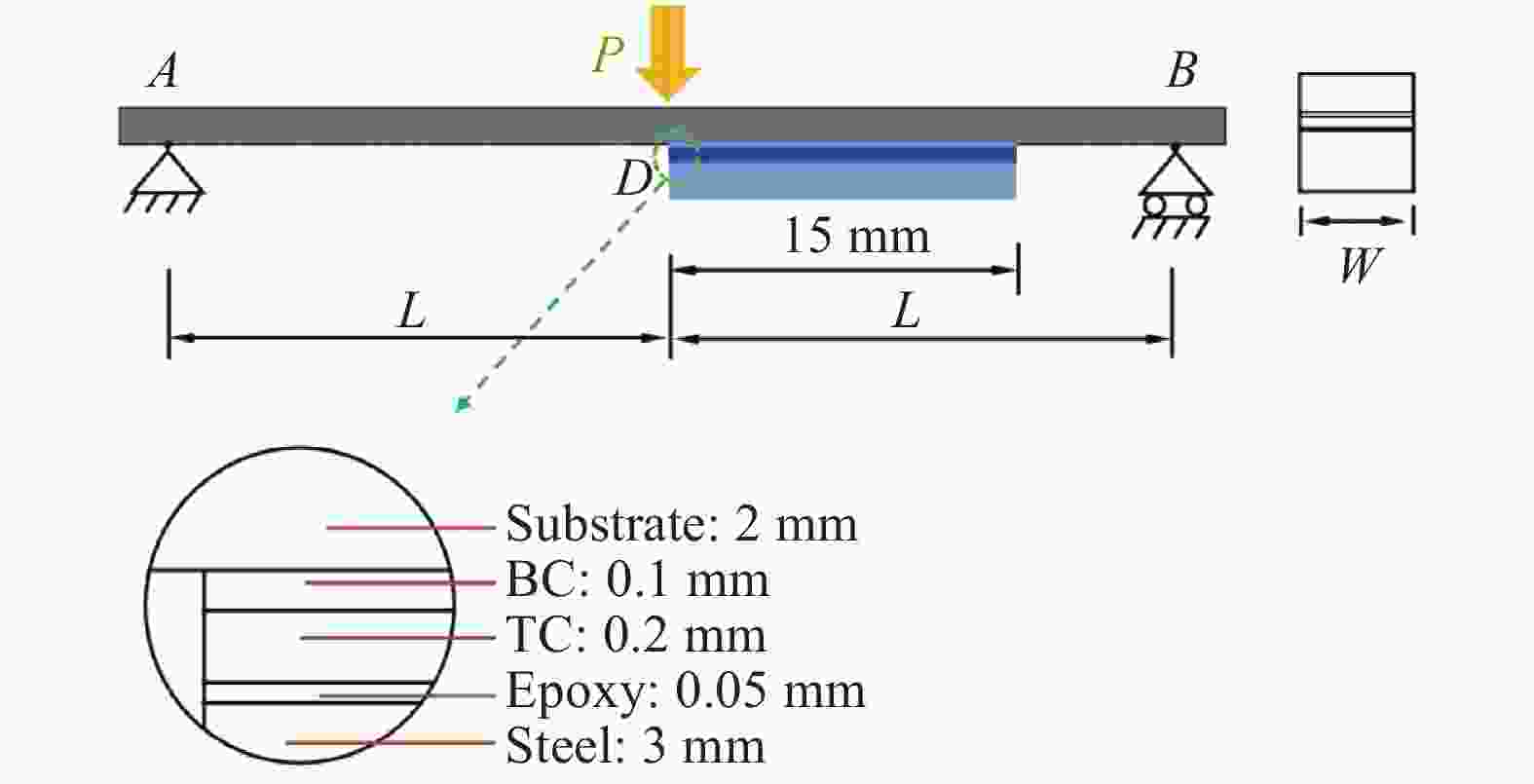

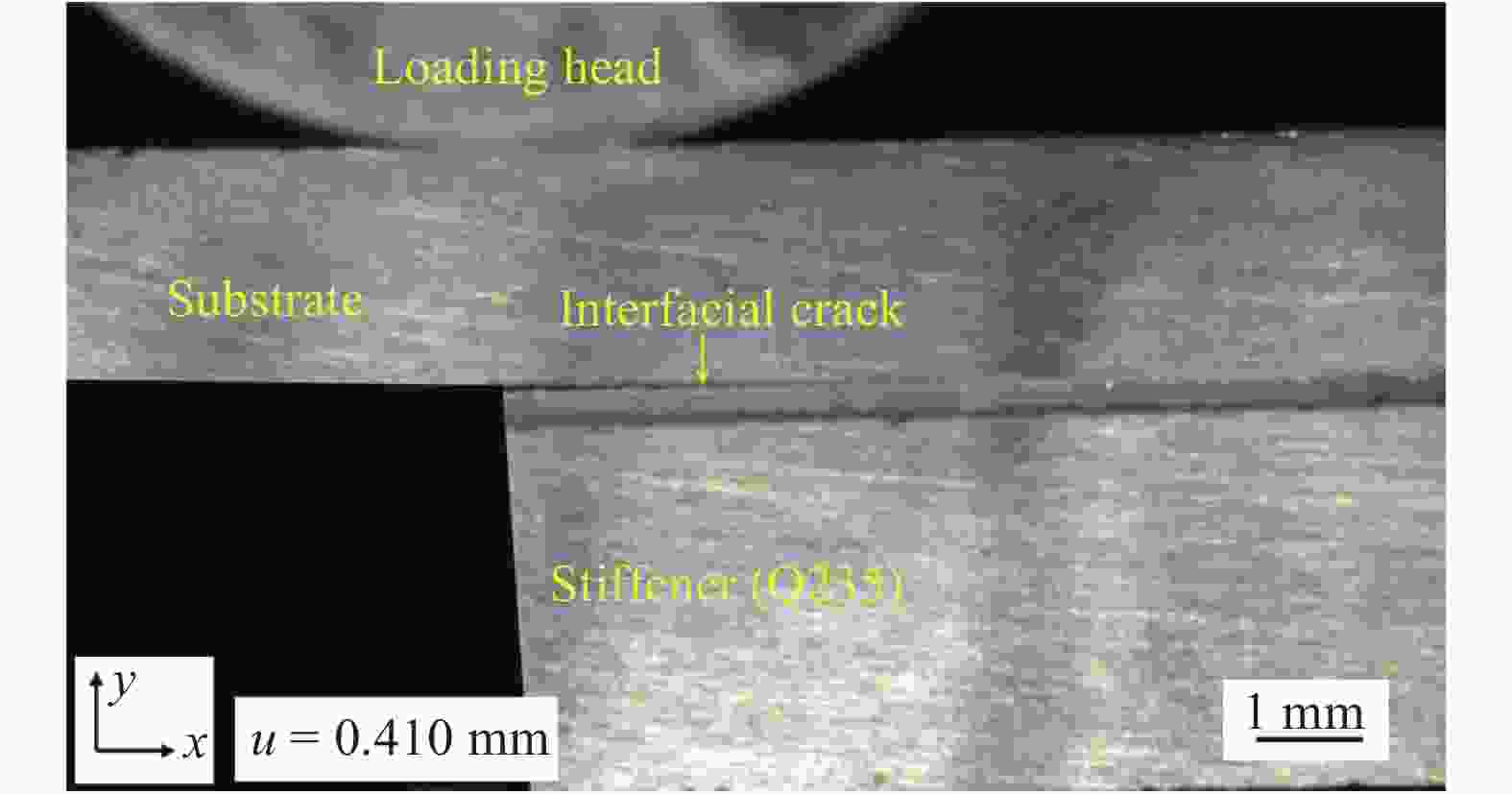

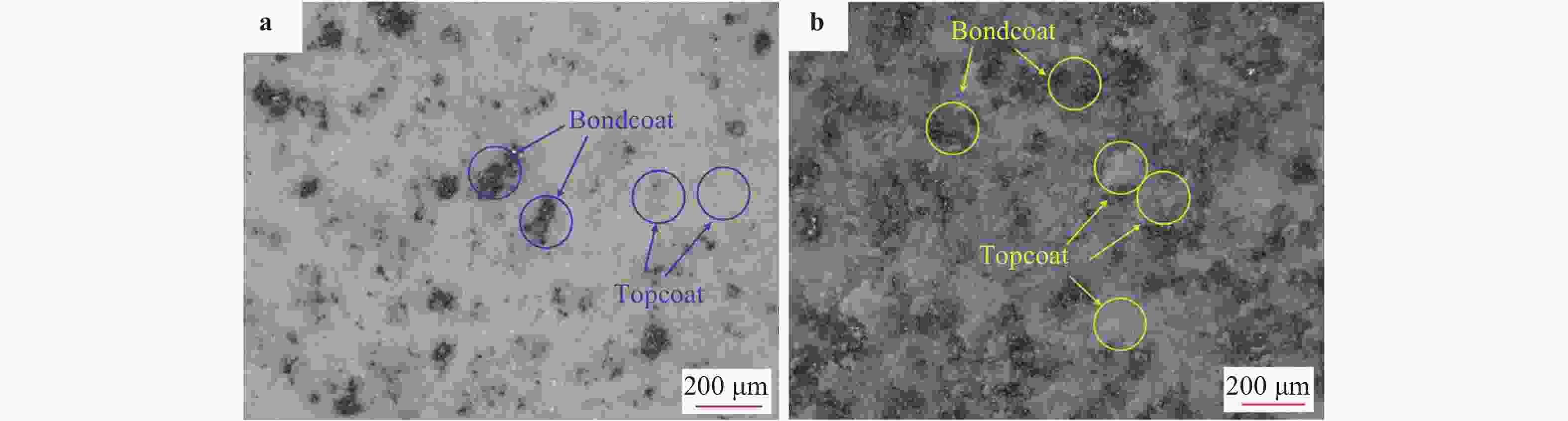

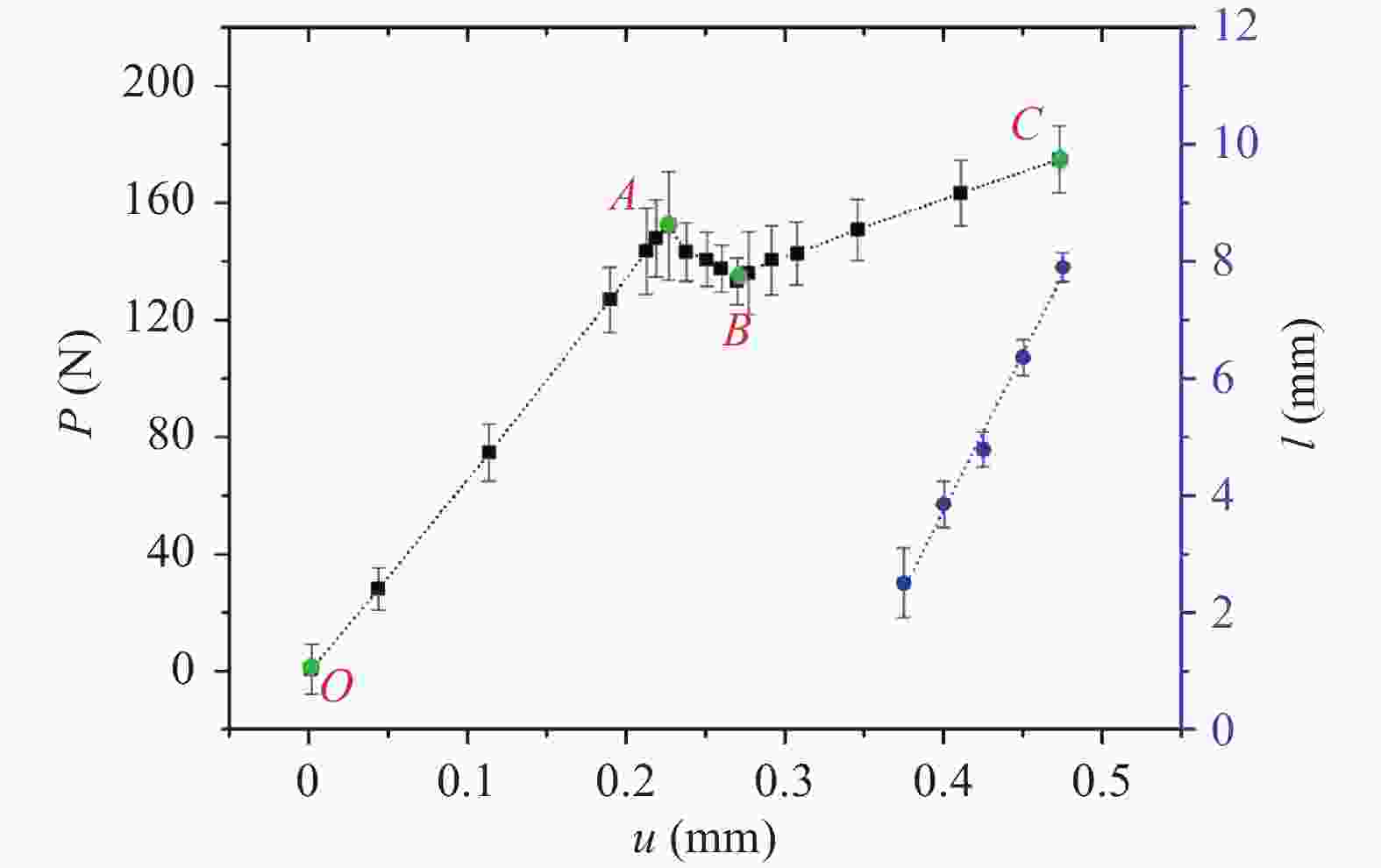

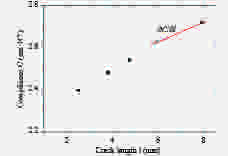

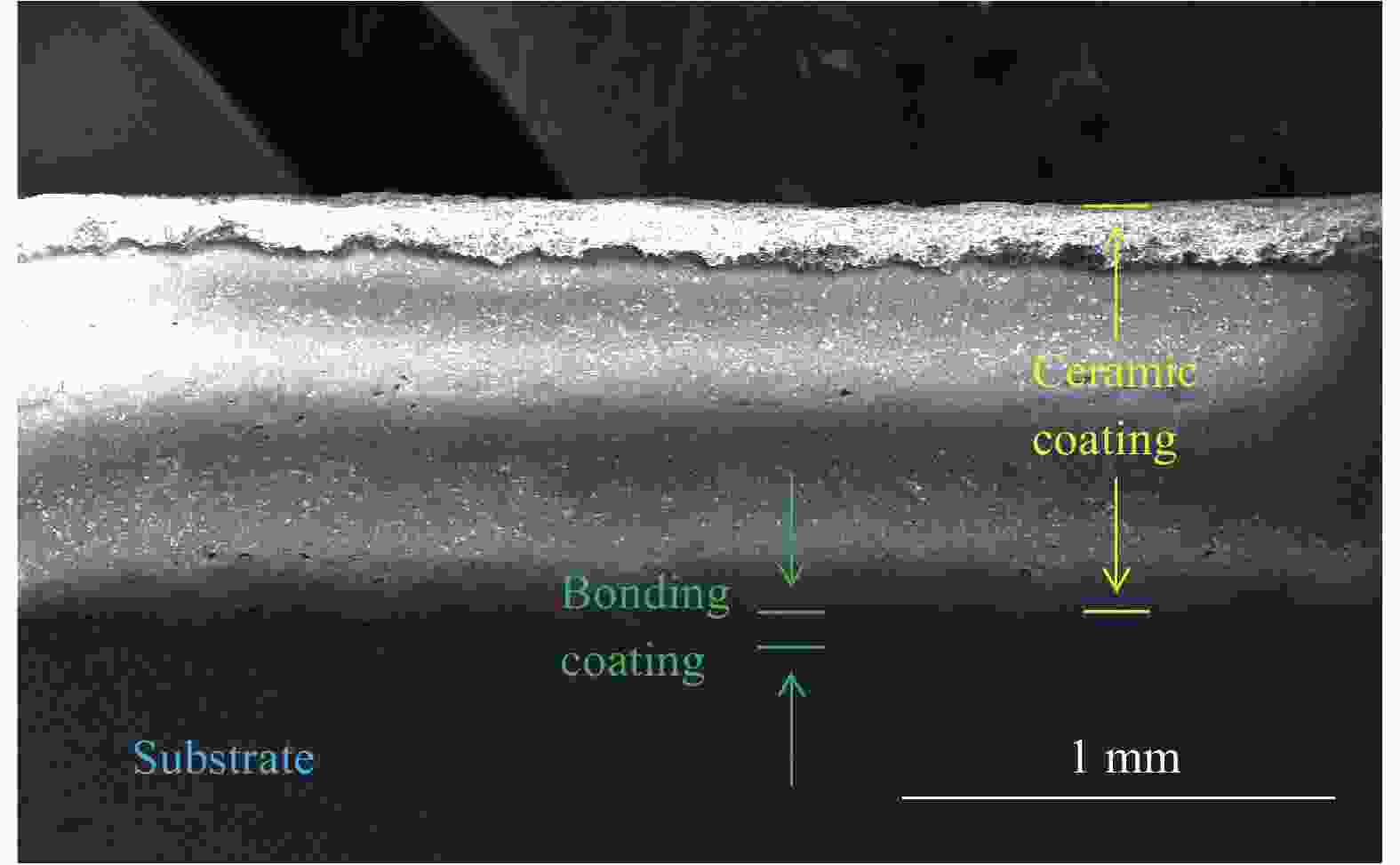

Determining the interfacial properties of thermal barrier coatings (TBCs) is imperative for their durability evaluation and further improvements. A ceramic coating (topcoat) and a NiCoCrALY bondcoat were atmospheric-plasma-sprayed (APS) on a stainless steel substrate. A modified three-point bending test was adopted to initiate and propagate the topcoat/bondcoat (TC/BC) interfacial crack. After a complete delamination, the fracture surfaces were examined by an optical microscope, which shows that the cracking plane was merely on the TC/BC interface. Based on the experimental results of load–displacement and crack length–displacement,the strain energy release rate G for crack propagation was calculated, and the averaged magnitude was 77.1 J/m2. Repeatable results have indicated that the method can be used for the evaluation of interfacial fracture toughness in thermal barrier coatings and other multi-layer structures.

Determining the interfacial properties of thermal barrier coatings (TBCs) is imperative for their durability evaluation and further improvements. A ceramic coating (topcoat) and a NiCoCrALY bondcoat were atmospheric-plasma-sprayed (APS) on a stainless steel substrate. A modified three-point bending test was adopted to initiate and propagate the topcoat/bondcoat (TC/BC) interfacial crack. After a complete delamination, the fracture surfaces were examined by an optical microscope, which shows that the cracking plane was merely on the TC/BC interface. Based on the experimental results of load–displacement and crack length–displacement,the strain energy release rate G for crack propagation was calculated, and the averaged magnitude was 77.1 J/m2. Repeatable results have indicated that the method can be used for the evaluation of interfacial fracture toughness in thermal barrier coatings and other multi-layer structures.

Theoretical and Applied Mechanics Letters 2018, 8(1): 7-11.

doi: 10.1016/j.taml.2018.01.007

Abstract:

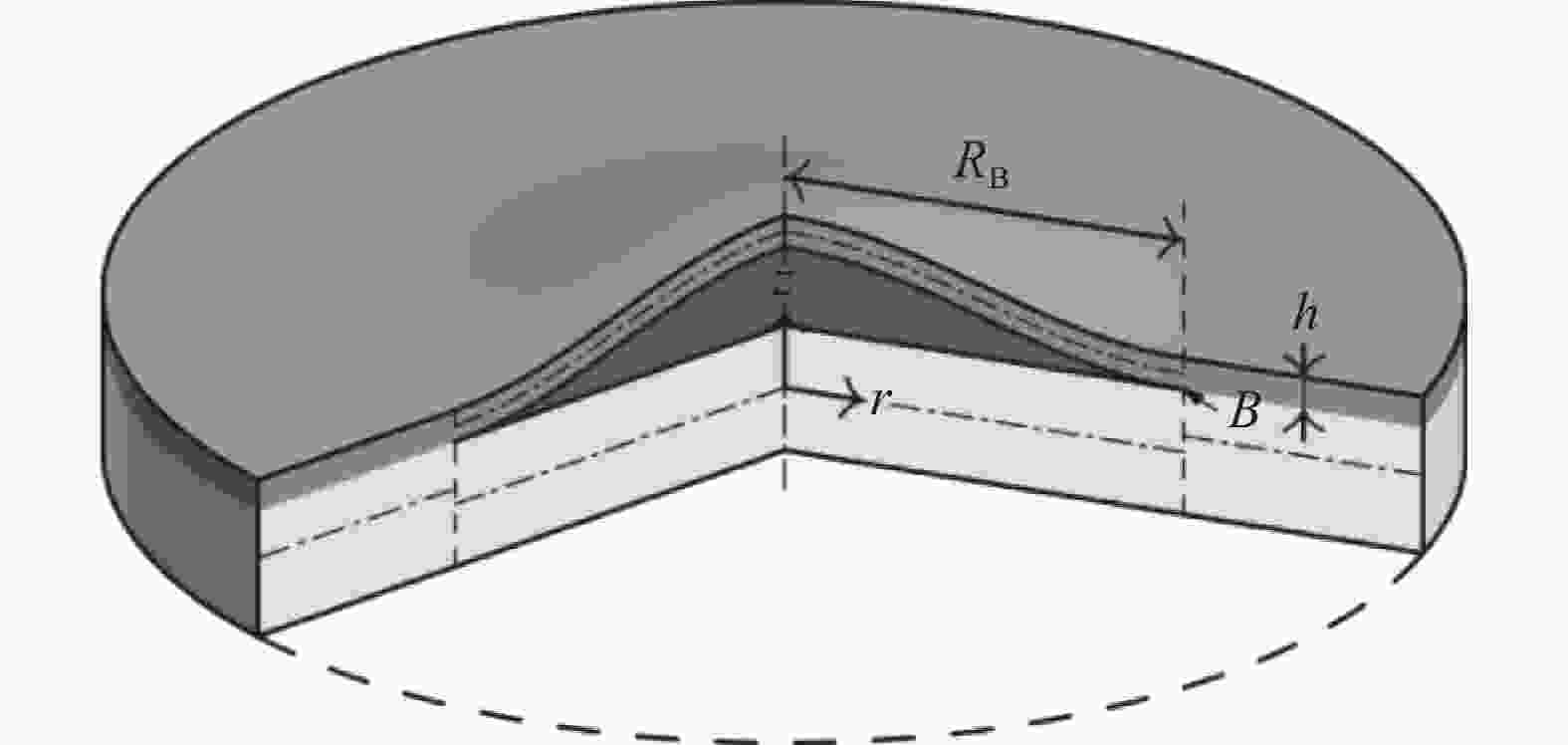

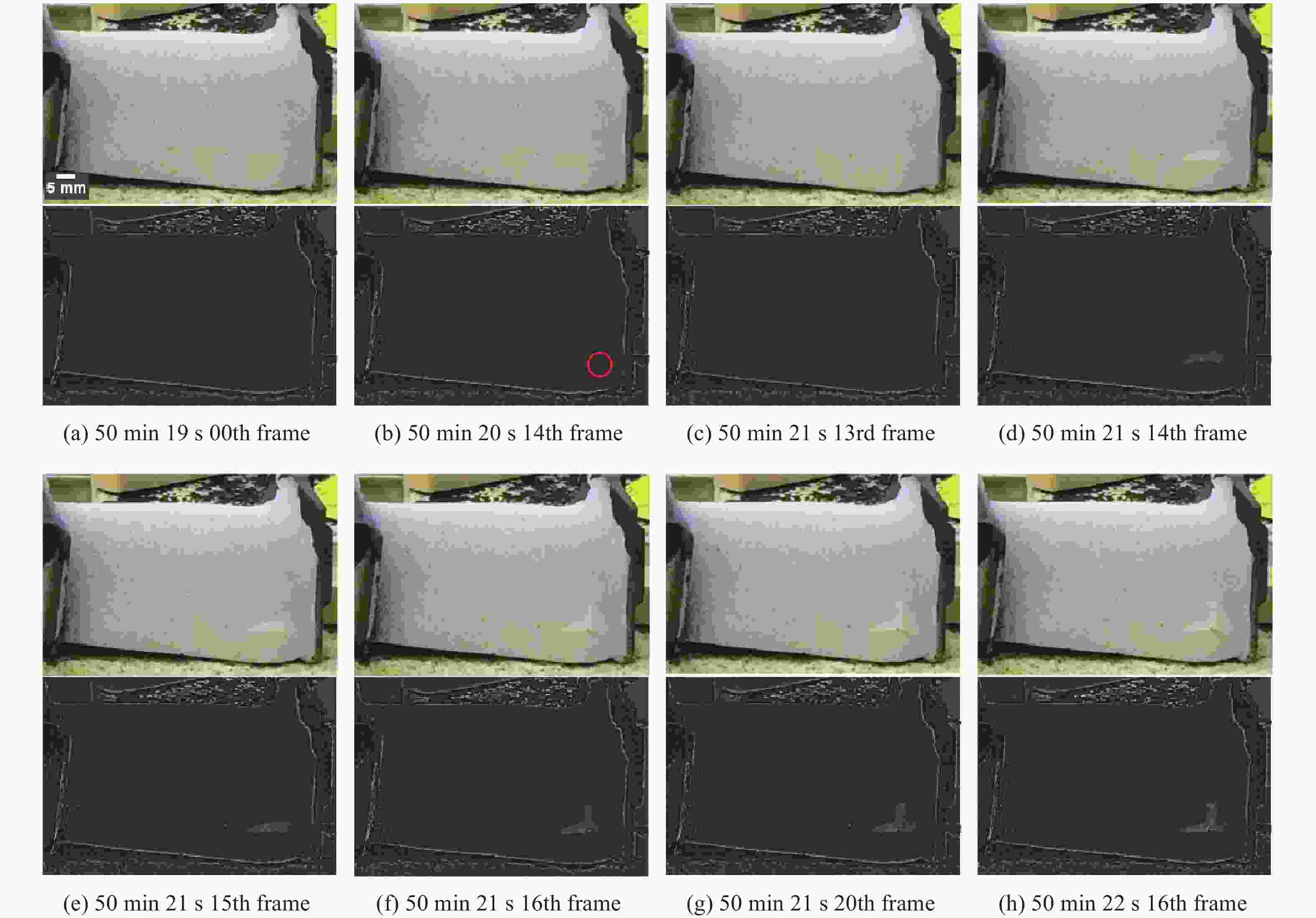

Laboratory experiments were conducted to study the spallation behaviour of thermal barrier coatings (TBCs) on aero-engine turbine blades manufactured by the electron-beam physical vapour deposition technique (EB-PVD). Intact blades were heated at temperature 1135°C in a furnace for certain time and then cooled to the room temperature in the laboratory condition. It was found that no spallation occurred during cooling, but spallation happened at constant room temperature after cooling. The spallation mechanism is studied by using the mechanical model developed (Harvey 2017 and Wang 2017), which are based on the hypothesis of pockets of energy concentration (PECs). Some observations of the spallation behaviour are well predicted by the model.

Laboratory experiments were conducted to study the spallation behaviour of thermal barrier coatings (TBCs) on aero-engine turbine blades manufactured by the electron-beam physical vapour deposition technique (EB-PVD). Intact blades were heated at temperature 1135°C in a furnace for certain time and then cooled to the room temperature in the laboratory condition. It was found that no spallation occurred during cooling, but spallation happened at constant room temperature after cooling. The spallation mechanism is studied by using the mechanical model developed (Harvey 2017 and Wang 2017), which are based on the hypothesis of pockets of energy concentration (PECs). Some observations of the spallation behaviour are well predicted by the model.

Theoretical and Applied Mechanics Letters 2018, 8(1): 12-17.

doi: 10.1016/j.taml.2018.01.004

Abstract:

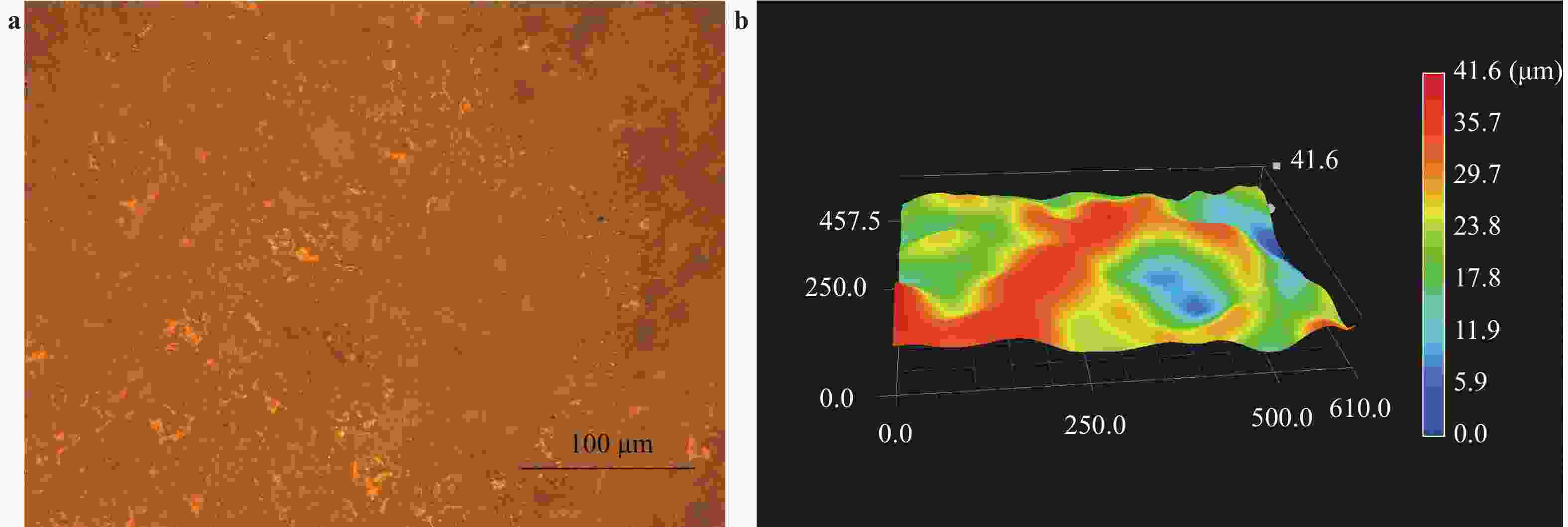

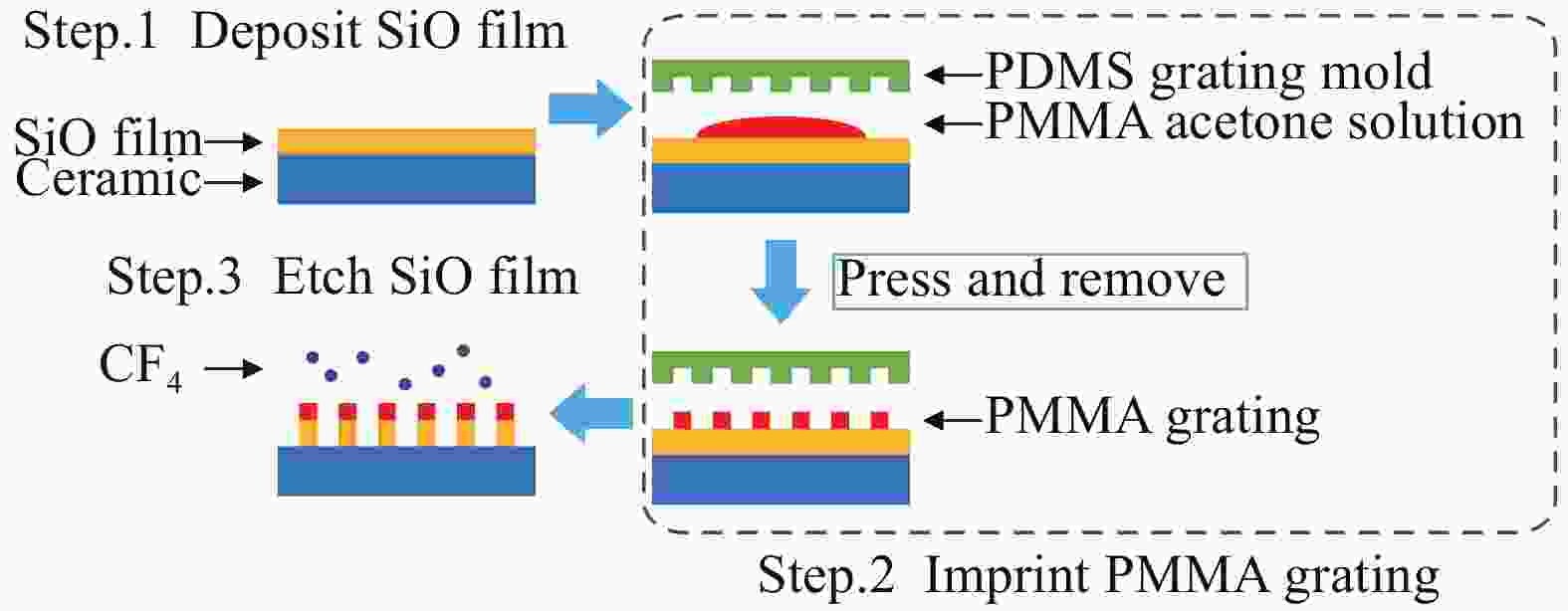

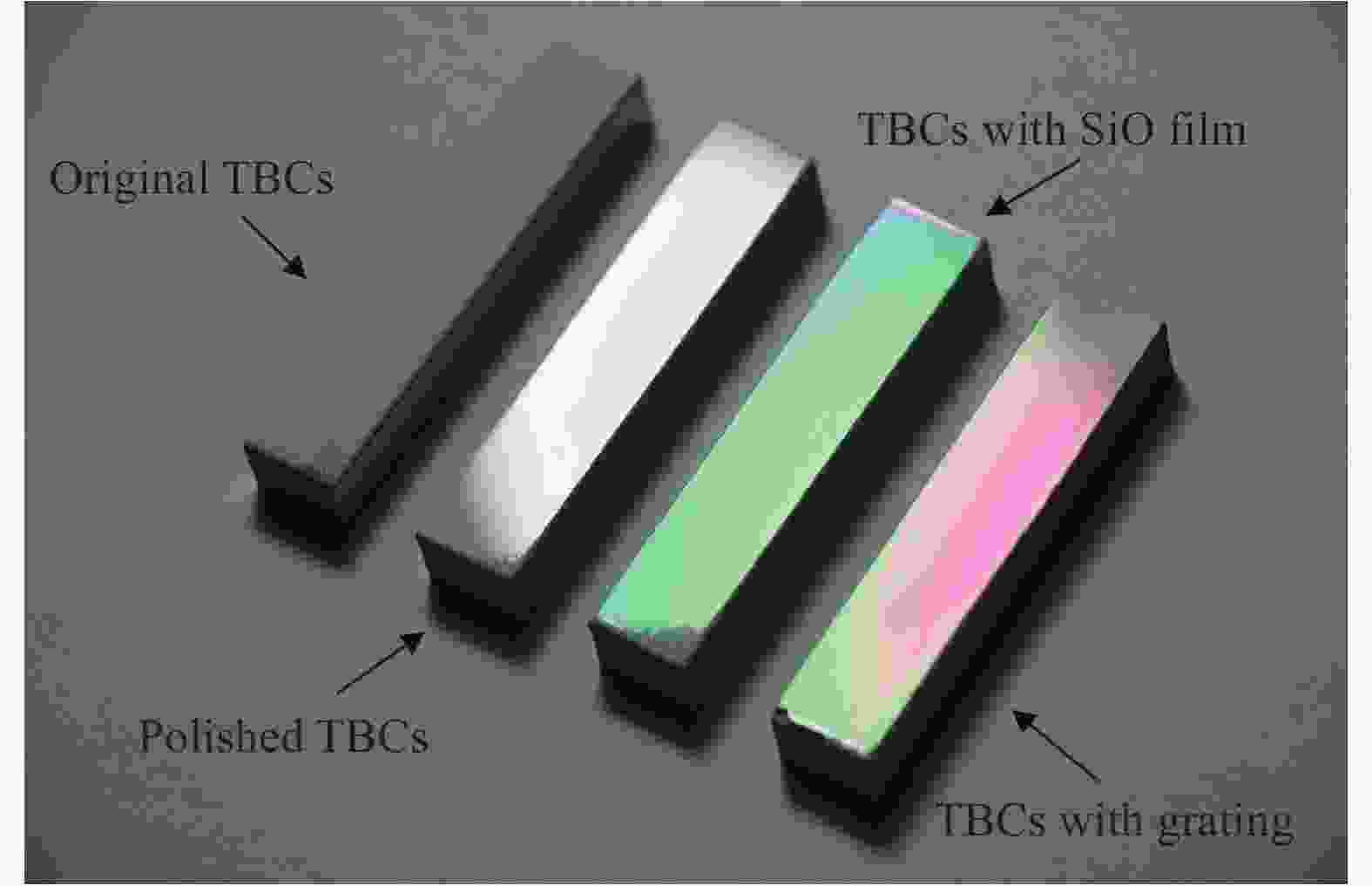

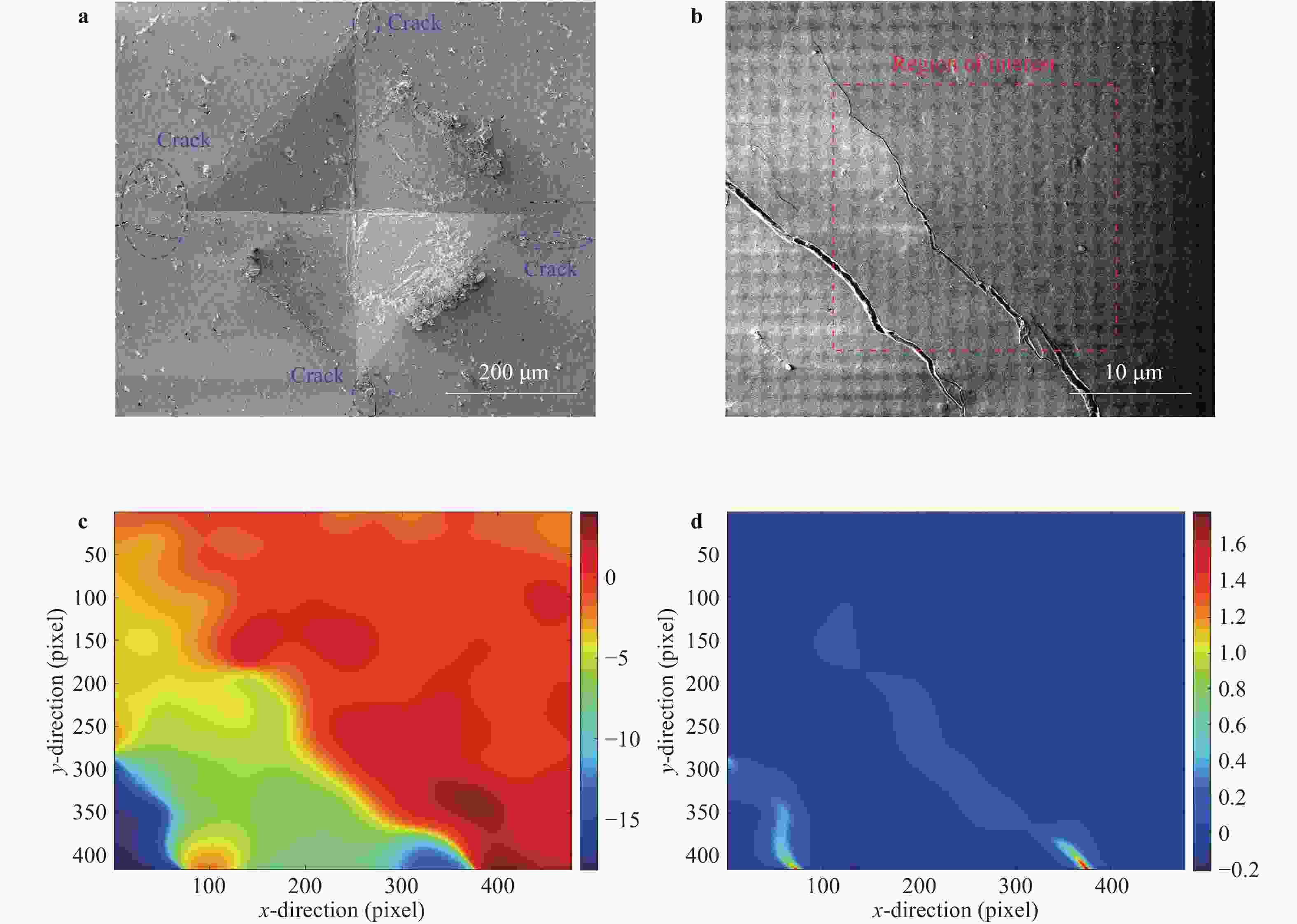

In this study, an etched-SiO-film grating fabrication technique based on solute-solvent separation soft lithography is developed. By using this new technique, high temperature grating with frequency of 600 lines/mm is successfully fabricated on the surface of thermal barrier coatings (TBCs). During the fabrication process, the microstructure and chemical compositions of ceramic coating before and after polishing is analyzed with a digital microscope and the energy dispersive X-ray spectroscope (EDS) in scanning electron microscope (SEM). And then the grating on TBCs is heated at the temperature ranging from 300°C to 1000°C for examining the high temperature resistance. In the practical application, the displacement and strain field around the crack on the ceramic surface are investigated with geometry phase analysis (GPA). The successful results verify that the etched-SiO-film grating has a good oxidation resistance and can be applied to high temperature deformation measurement of TBCs.

In this study, an etched-SiO-film grating fabrication technique based on solute-solvent separation soft lithography is developed. By using this new technique, high temperature grating with frequency of 600 lines/mm is successfully fabricated on the surface of thermal barrier coatings (TBCs). During the fabrication process, the microstructure and chemical compositions of ceramic coating before and after polishing is analyzed with a digital microscope and the energy dispersive X-ray spectroscope (EDS) in scanning electron microscope (SEM). And then the grating on TBCs is heated at the temperature ranging from 300°C to 1000°C for examining the high temperature resistance. In the practical application, the displacement and strain field around the crack on the ceramic surface are investigated with geometry phase analysis (GPA). The successful results verify that the etched-SiO-film grating has a good oxidation resistance and can be applied to high temperature deformation measurement of TBCs.

Theoretical and Applied Mechanics Letters 2018, 8(1): 18-23.

doi: 10.1016/j.taml.2018.01.003

Abstract:

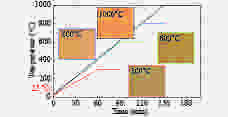

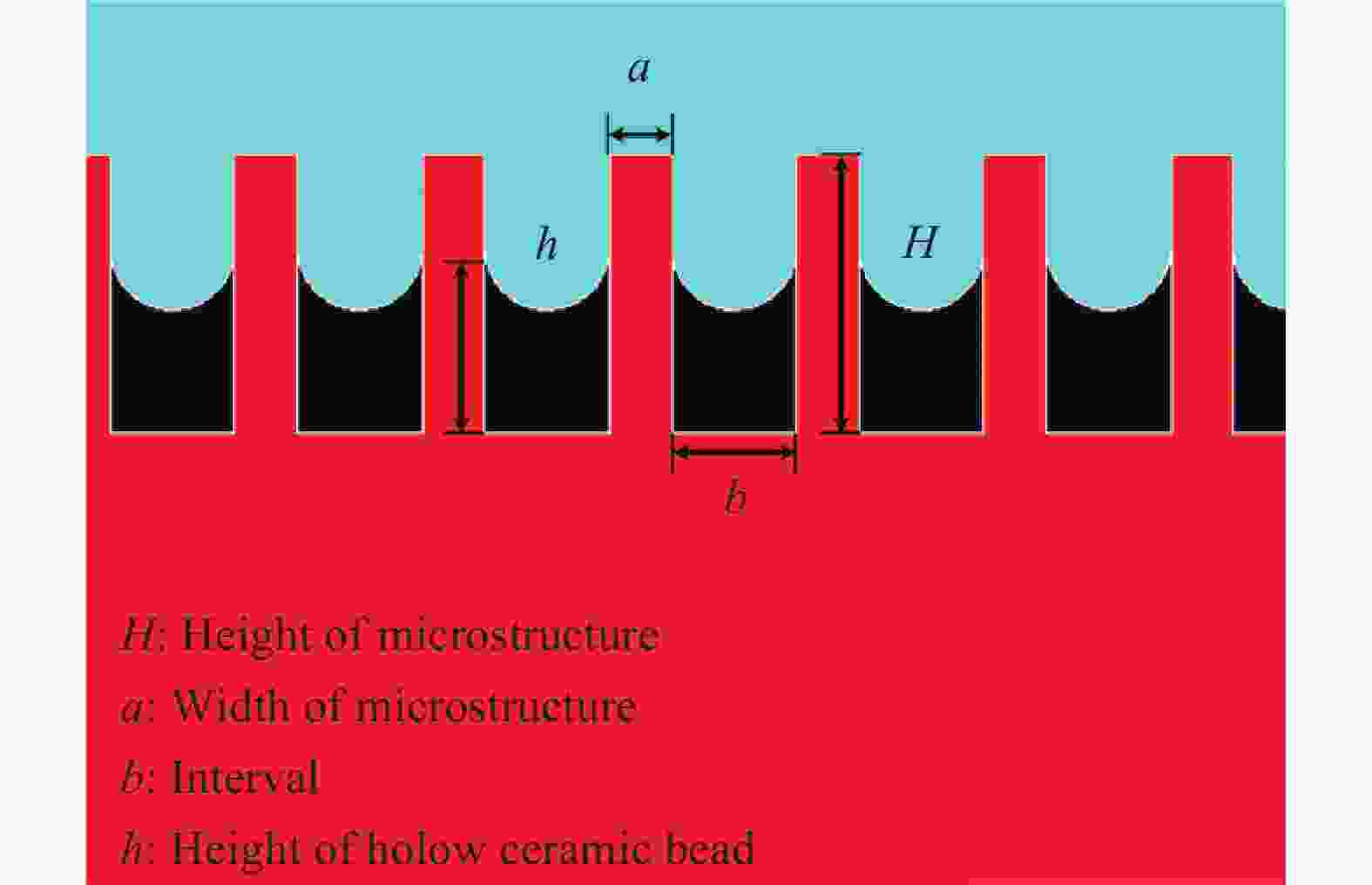

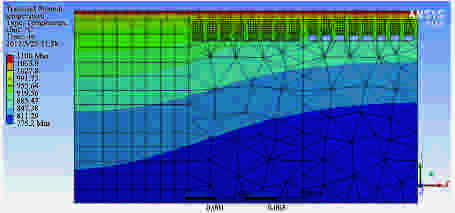

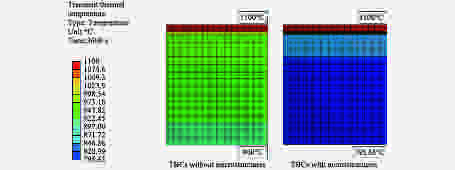

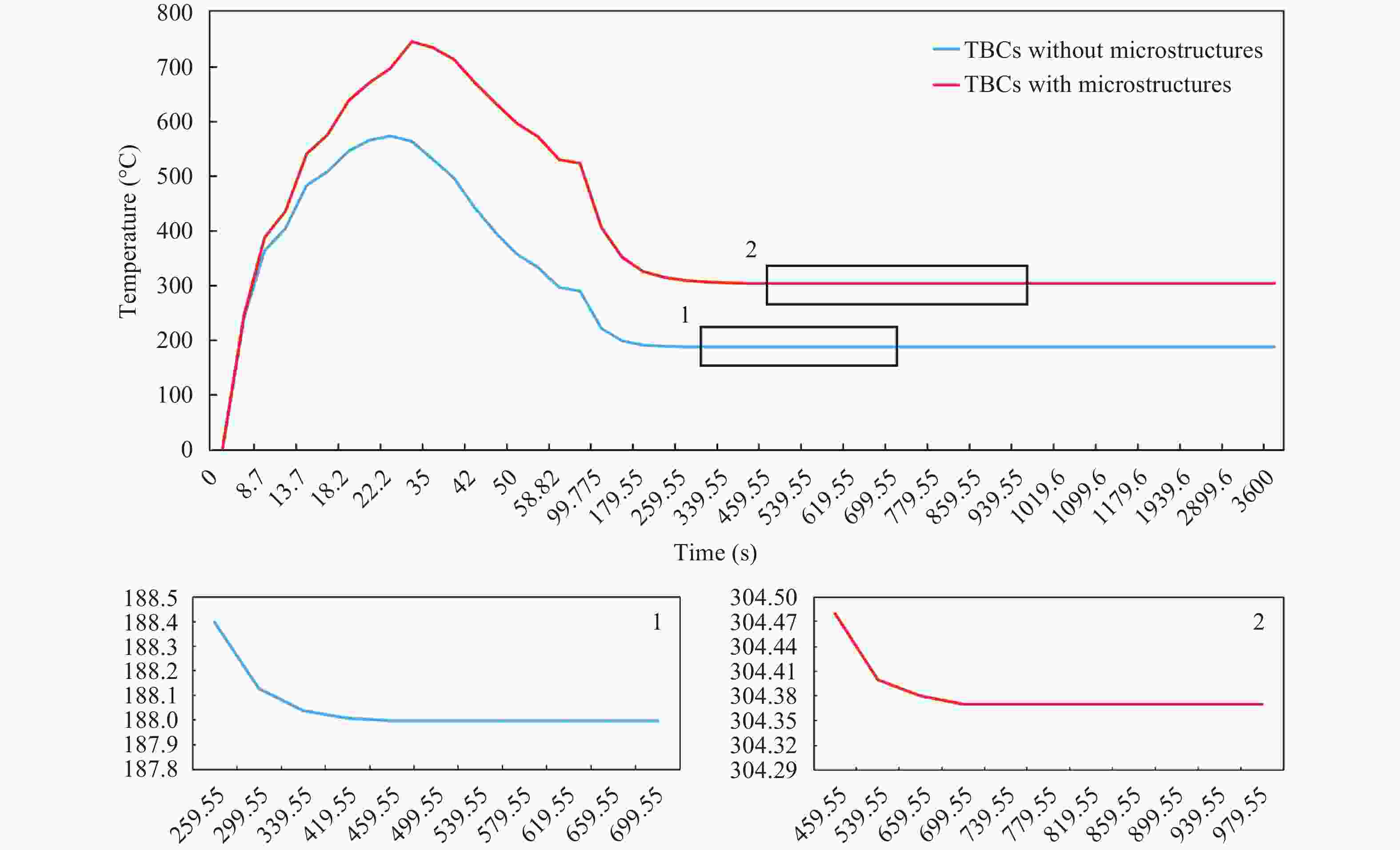

The insulation effect of ceramic coating in a turbine blade is of great importance for the service of engine in the field of aviation industry. Fabricating microstructure in the thermal barrier coatings (TBCs) is considered to be able to enhance the thermal insulation effect. In this study, the traditional three-layer structure, containing ceramic top coat, bonding coat and substrate, is firstly simplified into a double-layer structure, where only ceramic layer and substrate are left, for analyzing the thermal insulation. Afterwards, the thermal insulation effect of the designed microstructure in the bonding coat of the three-layer structure is further studied. Column-like microstructures, filled with hollow ceramic microspheres in the interspace, are designed to improve the thermal insulation effect. The size parameters of the designed microstructure were optimized. The existence of the designed microstructure can significantly prolong the efficiency of thermal barrier coatings. The insulation temperature between the heating surface and lower surface of the substrate can exceed 300°C and the thermal balance time has a big improvement of 240 s, more than 50%, than the traditional TBCs structure. Compared with the TBCs structure without microstructure, the designed microstructure can significantly improve the insulation temperature of more than 110°C.

The insulation effect of ceramic coating in a turbine blade is of great importance for the service of engine in the field of aviation industry. Fabricating microstructure in the thermal barrier coatings (TBCs) is considered to be able to enhance the thermal insulation effect. In this study, the traditional three-layer structure, containing ceramic top coat, bonding coat and substrate, is firstly simplified into a double-layer structure, where only ceramic layer and substrate are left, for analyzing the thermal insulation. Afterwards, the thermal insulation effect of the designed microstructure in the bonding coat of the three-layer structure is further studied. Column-like microstructures, filled with hollow ceramic microspheres in the interspace, are designed to improve the thermal insulation effect. The size parameters of the designed microstructure were optimized. The existence of the designed microstructure can significantly prolong the efficiency of thermal barrier coatings. The insulation temperature between the heating surface and lower surface of the substrate can exceed 300°C and the thermal balance time has a big improvement of 240 s, more than 50%, than the traditional TBCs structure. Compared with the TBCs structure without microstructure, the designed microstructure can significantly improve the insulation temperature of more than 110°C.

Theoretical and Applied Mechanics Letters 2018, 8(1): 24-27.

doi: 10.1016/j.taml.2018.01.008

Abstract:

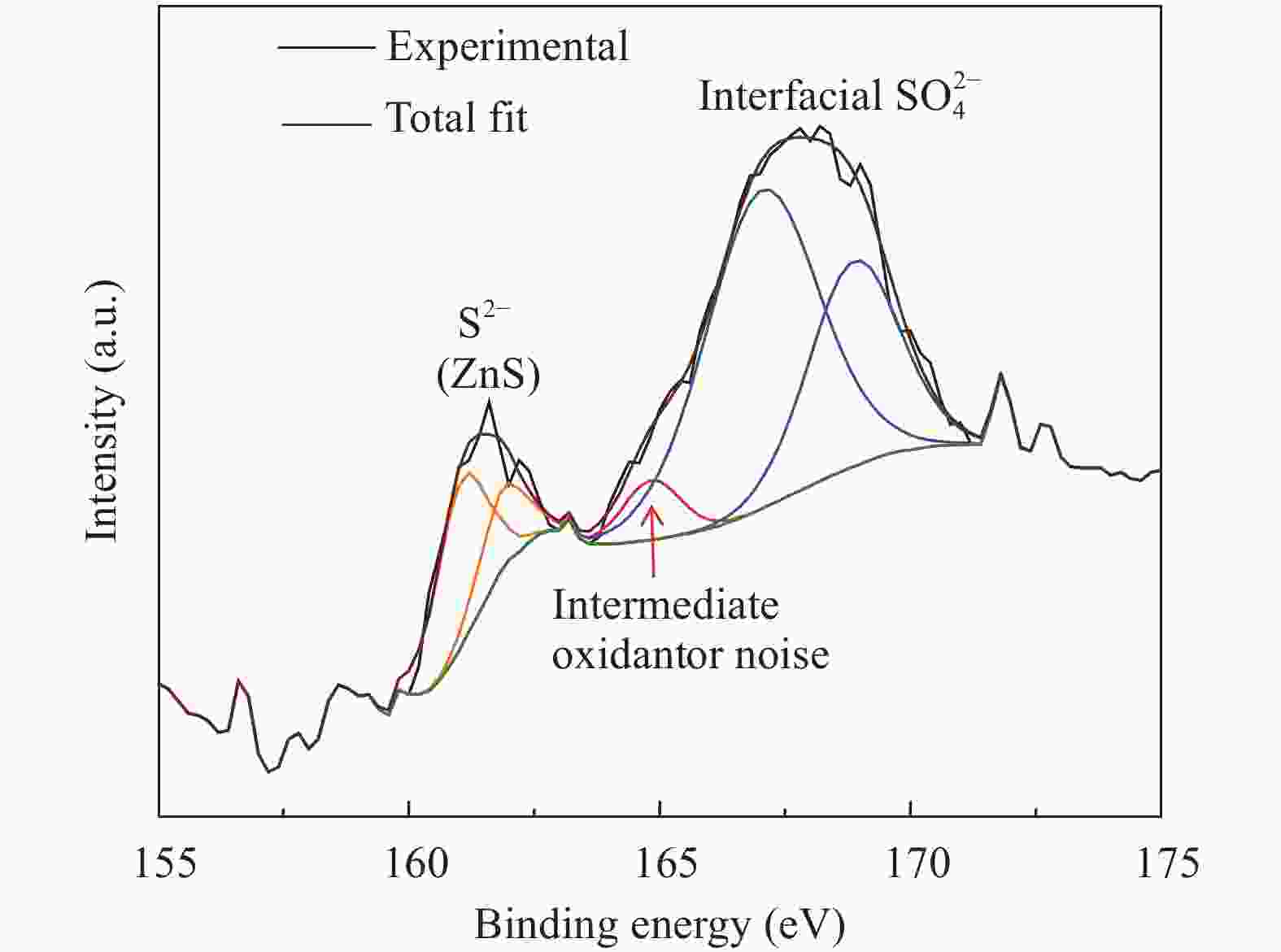

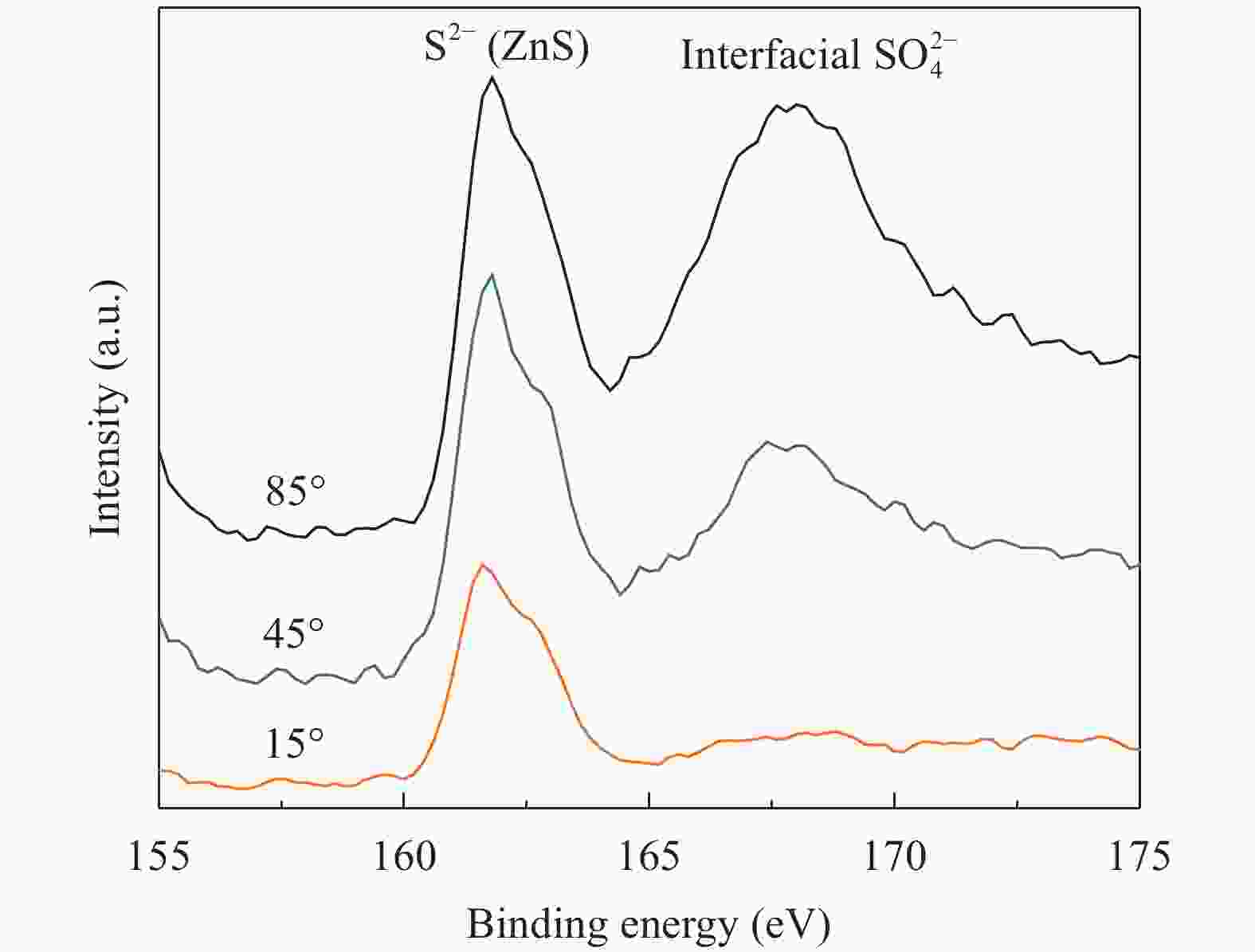

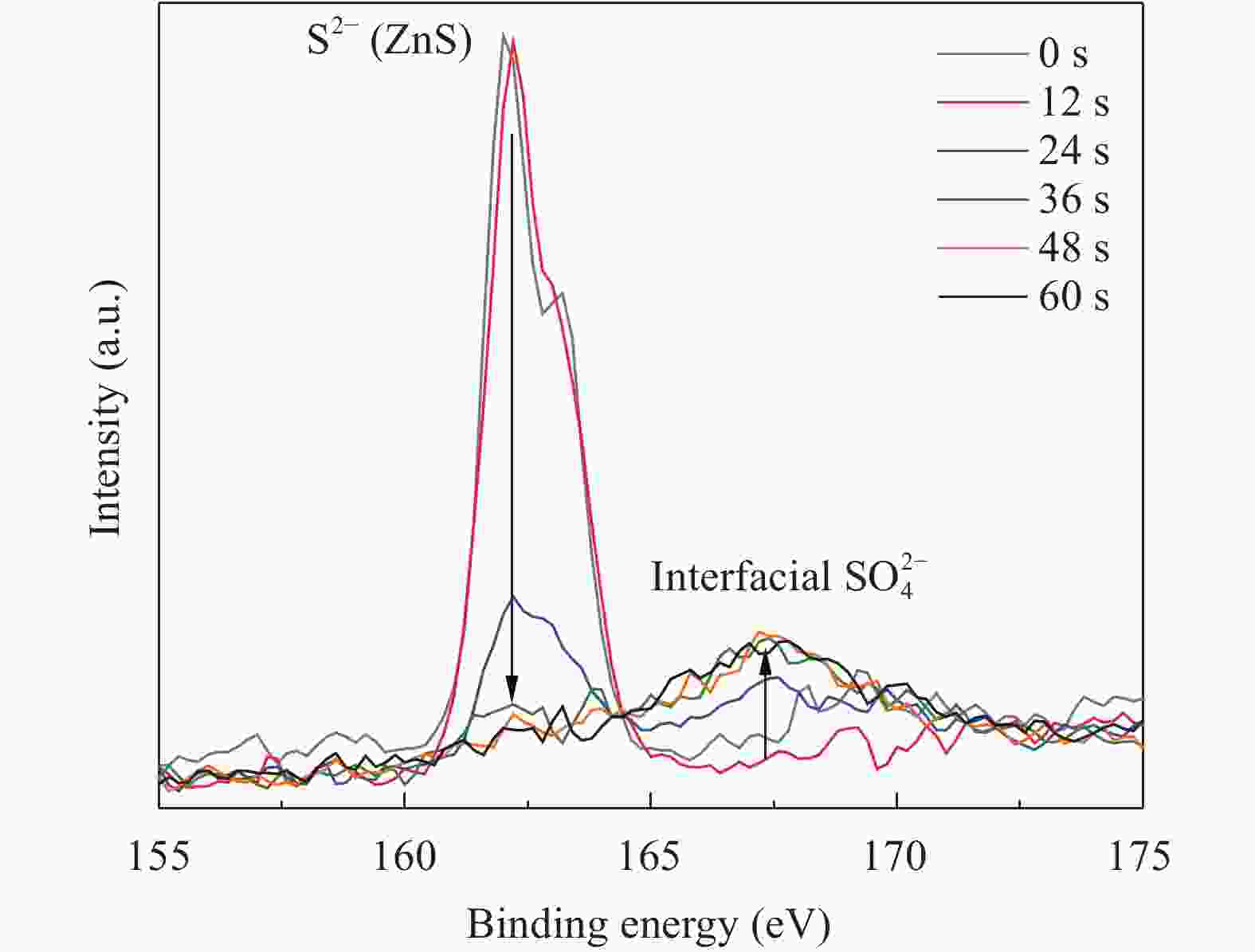

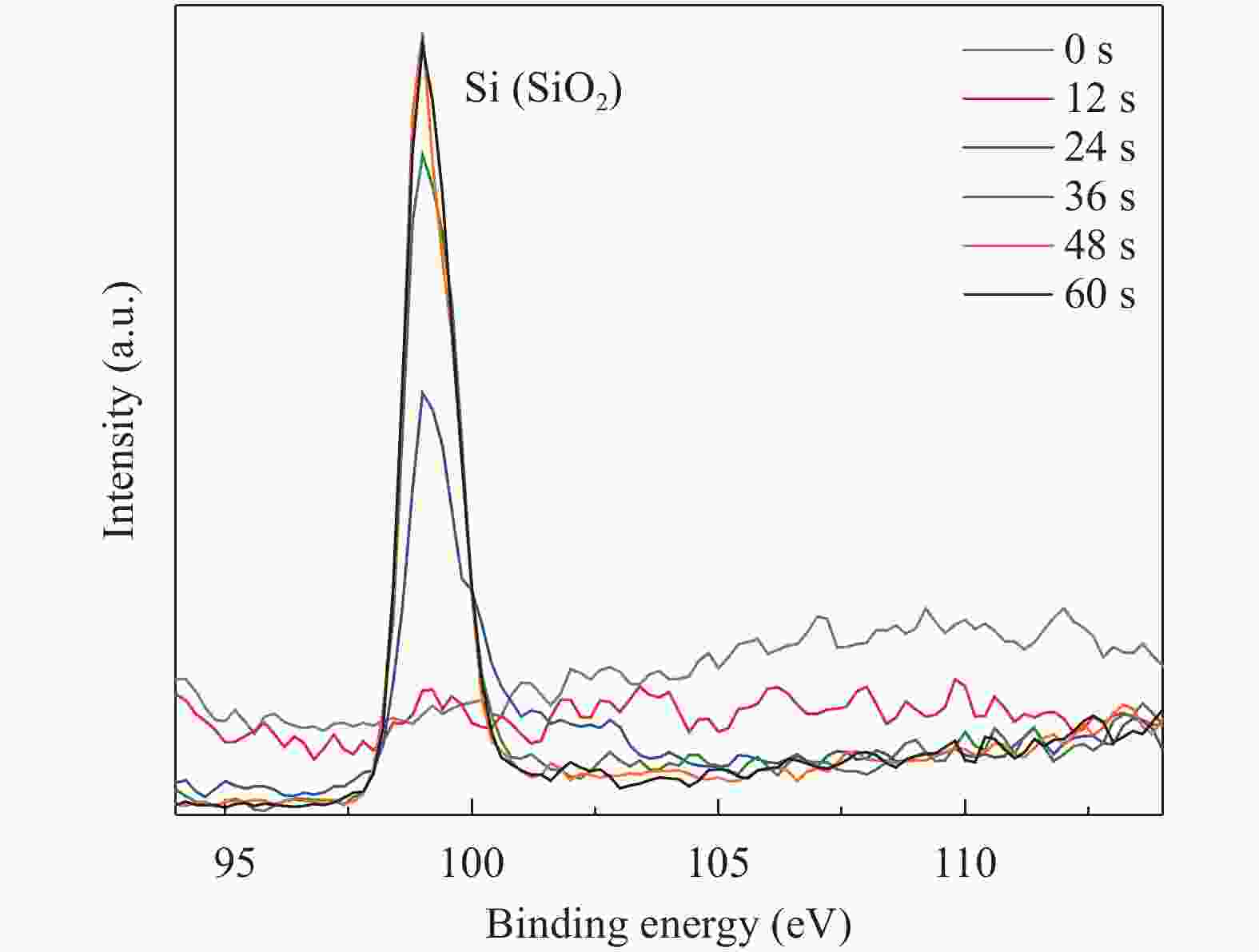

Sharp interfaces in optoelectronic devices are key for proper band alignment. Despite its benefits as buffer layer, ZnS deposited via atomic layer deposition (ALD) renders intermixed interfaces to its substrate, which can be detrimental for device performance. Here, we are attempting to elucidate the chemical species deriving from this metal-oxide to metal-sulfide transition studying ultrathin film ZnS on SiO2 using high resolution X-ray photoluminescence spectroscopy (XPS). Regarding the S 2p spectra after a deposition of only three cycles of ZnS, we discover the many different chemical species in which S is present. These include intermediate oxides such as SO42-. These species become more obvious as we tilt the sample in the XPS chamber to shallower angles. Comparing the Si 2p and S 2p high resolution peaks in the depth profile, one can clearly uncover the confinement of SO42- to the interface of the underlying substrate. This may indicate that SiO2/ZnS interfaces contain interfacial sulphates that likely alter the electronic configuration of this interface.

Sharp interfaces in optoelectronic devices are key for proper band alignment. Despite its benefits as buffer layer, ZnS deposited via atomic layer deposition (ALD) renders intermixed interfaces to its substrate, which can be detrimental for device performance. Here, we are attempting to elucidate the chemical species deriving from this metal-oxide to metal-sulfide transition studying ultrathin film ZnS on SiO2 using high resolution X-ray photoluminescence spectroscopy (XPS). Regarding the S 2p spectra after a deposition of only three cycles of ZnS, we discover the many different chemical species in which S is present. These include intermediate oxides such as SO42-. These species become more obvious as we tilt the sample in the XPS chamber to shallower angles. Comparing the Si 2p and S 2p high resolution peaks in the depth profile, one can clearly uncover the confinement of SO42- to the interface of the underlying substrate. This may indicate that SiO2/ZnS interfaces contain interfacial sulphates that likely alter the electronic configuration of this interface.

Theoretical and Applied Mechanics Letters 2018, 8(1): 28-31.

doi: 10.1016/j.taml.2017.11.002

Abstract:

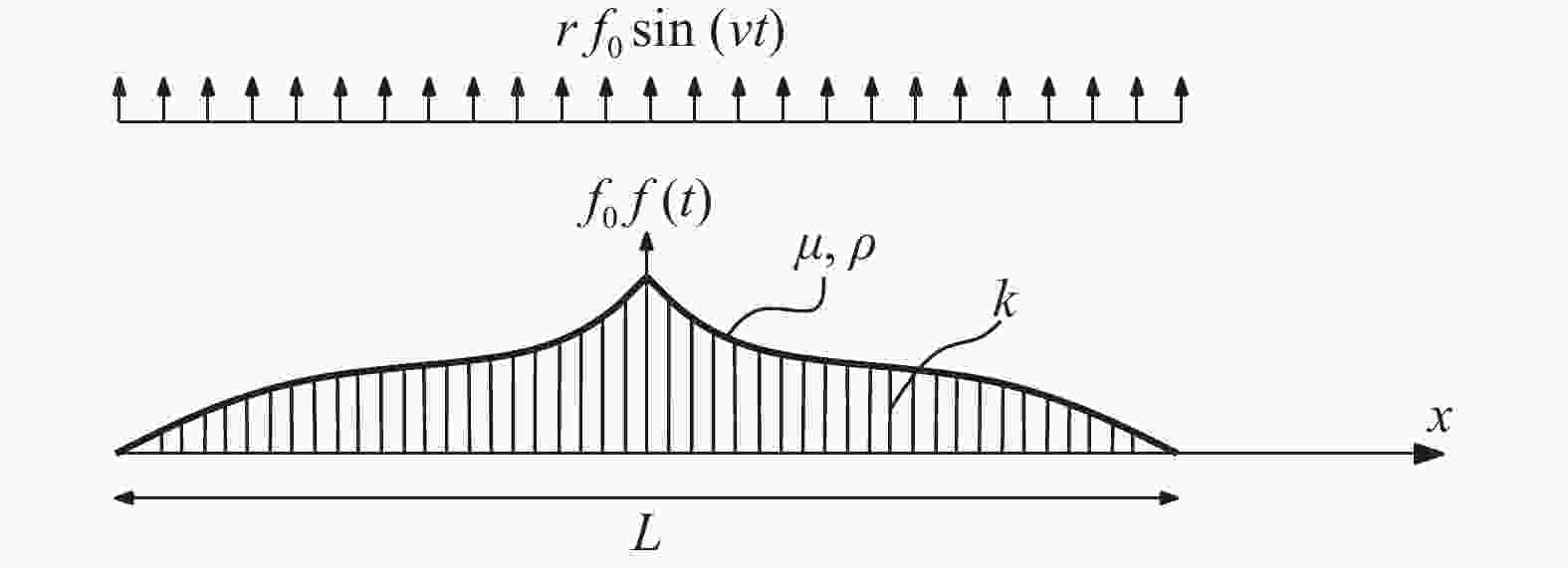

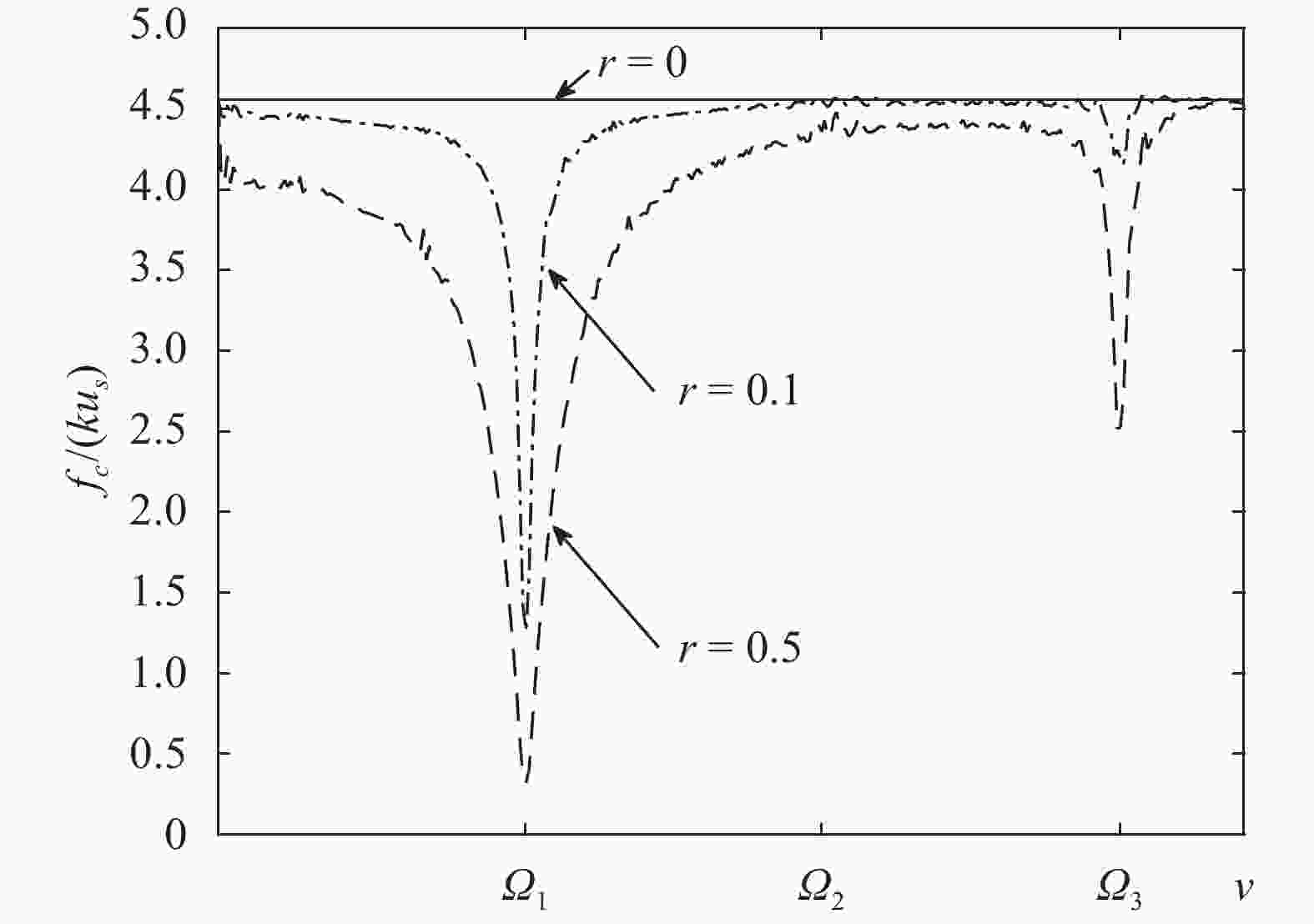

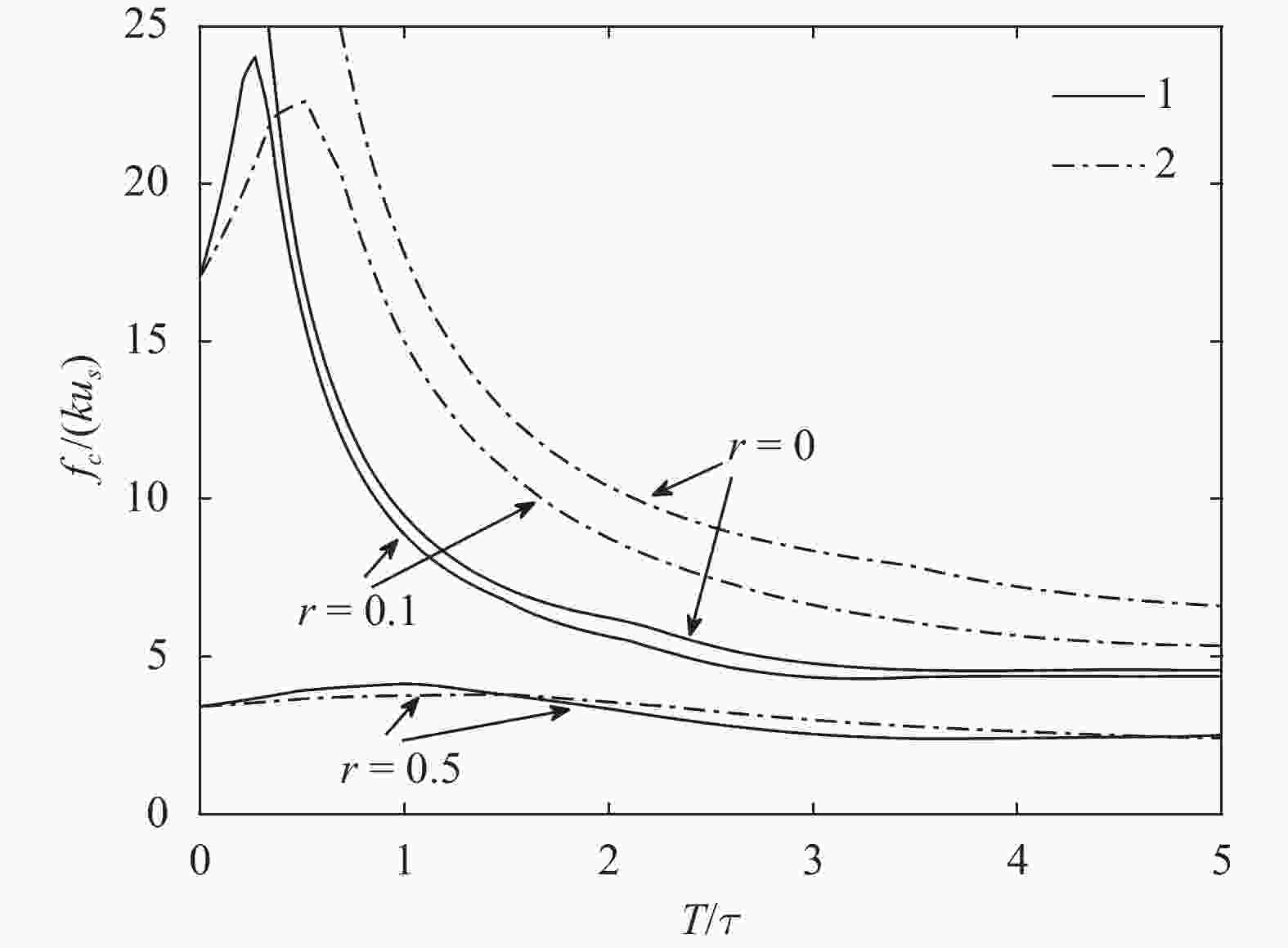

In the present work, we analyse the delamination problem under the combined dynamic load. We show the effect of background harmonic vibrations on critical amplitudes of the principal force pulse. The effect is demonstrated on the simple model of a string on an elastic foundation and the fracture phenomenon is predicted by the incubation time criterion. The results state the possibility of considerable decrease in threshold amplitude by a proper choice of the frequency of a background excitation.

In the present work, we analyse the delamination problem under the combined dynamic load. We show the effect of background harmonic vibrations on critical amplitudes of the principal force pulse. The effect is demonstrated on the simple model of a string on an elastic foundation and the fracture phenomenon is predicted by the incubation time criterion. The results state the possibility of considerable decrease in threshold amplitude by a proper choice of the frequency of a background excitation.

Theoretical and Applied Mechanics Letters 2018, 8(1): 32-42.

doi: 10.1016/j.taml.2018.01.009

Abstract:

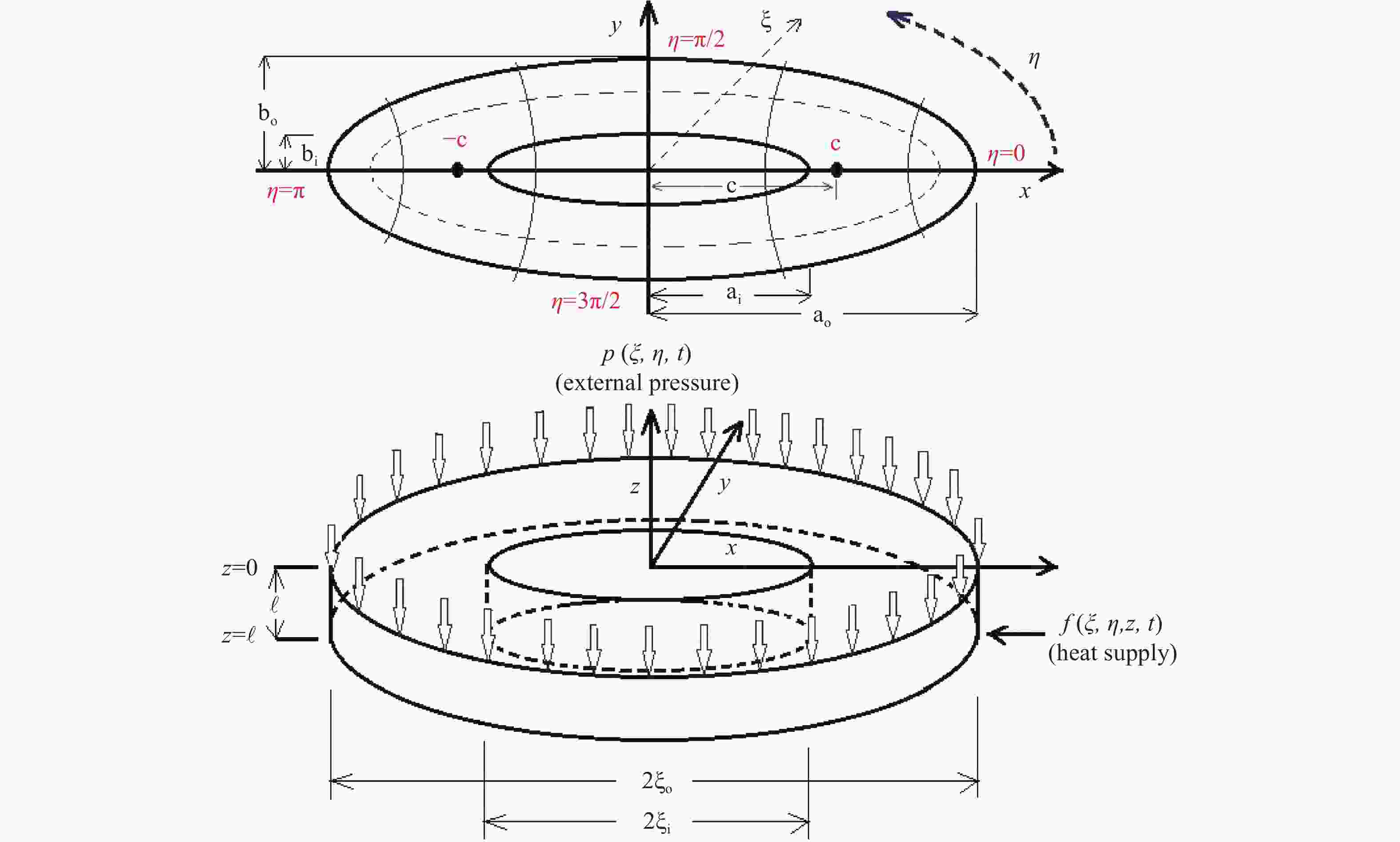

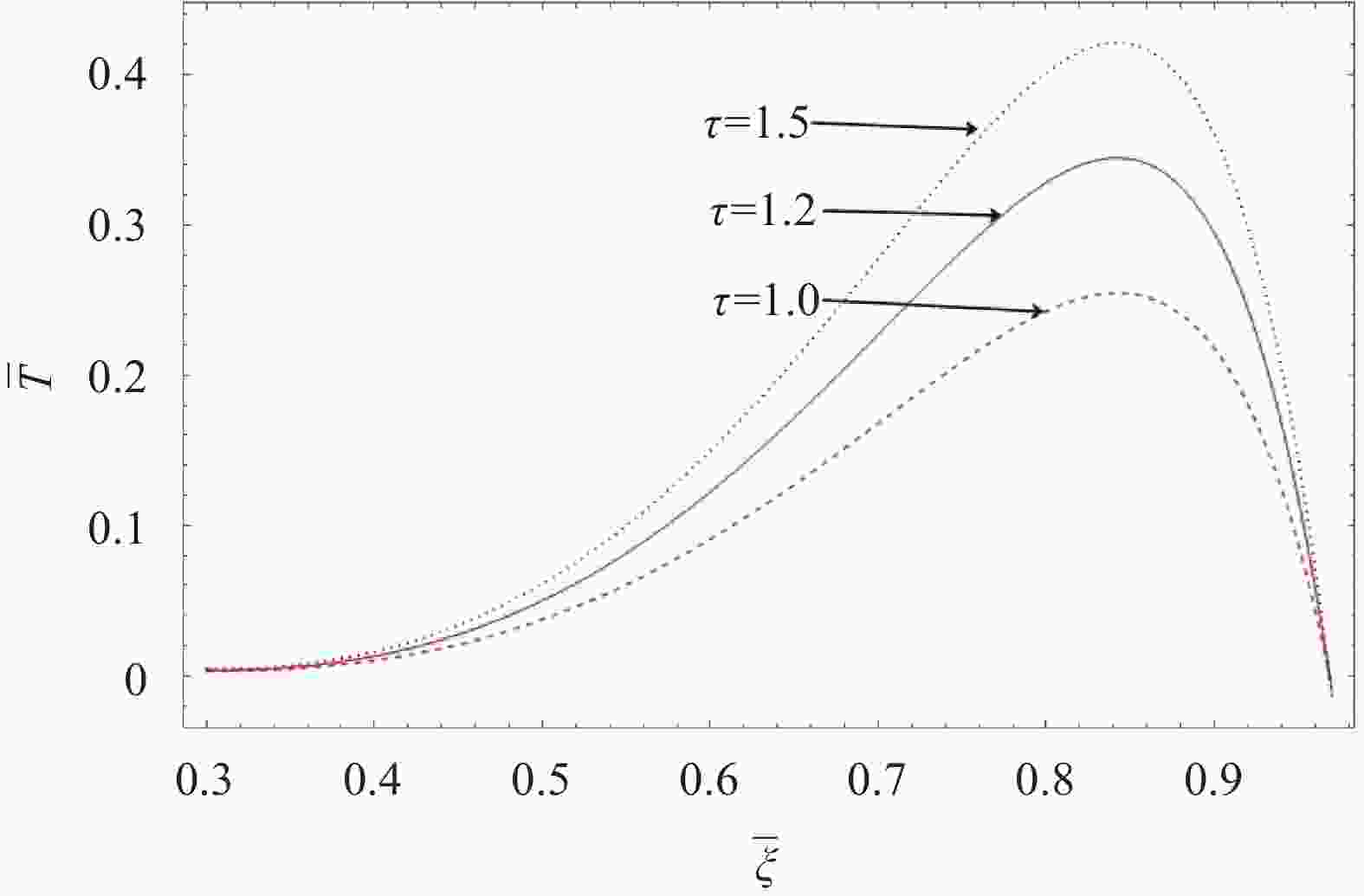

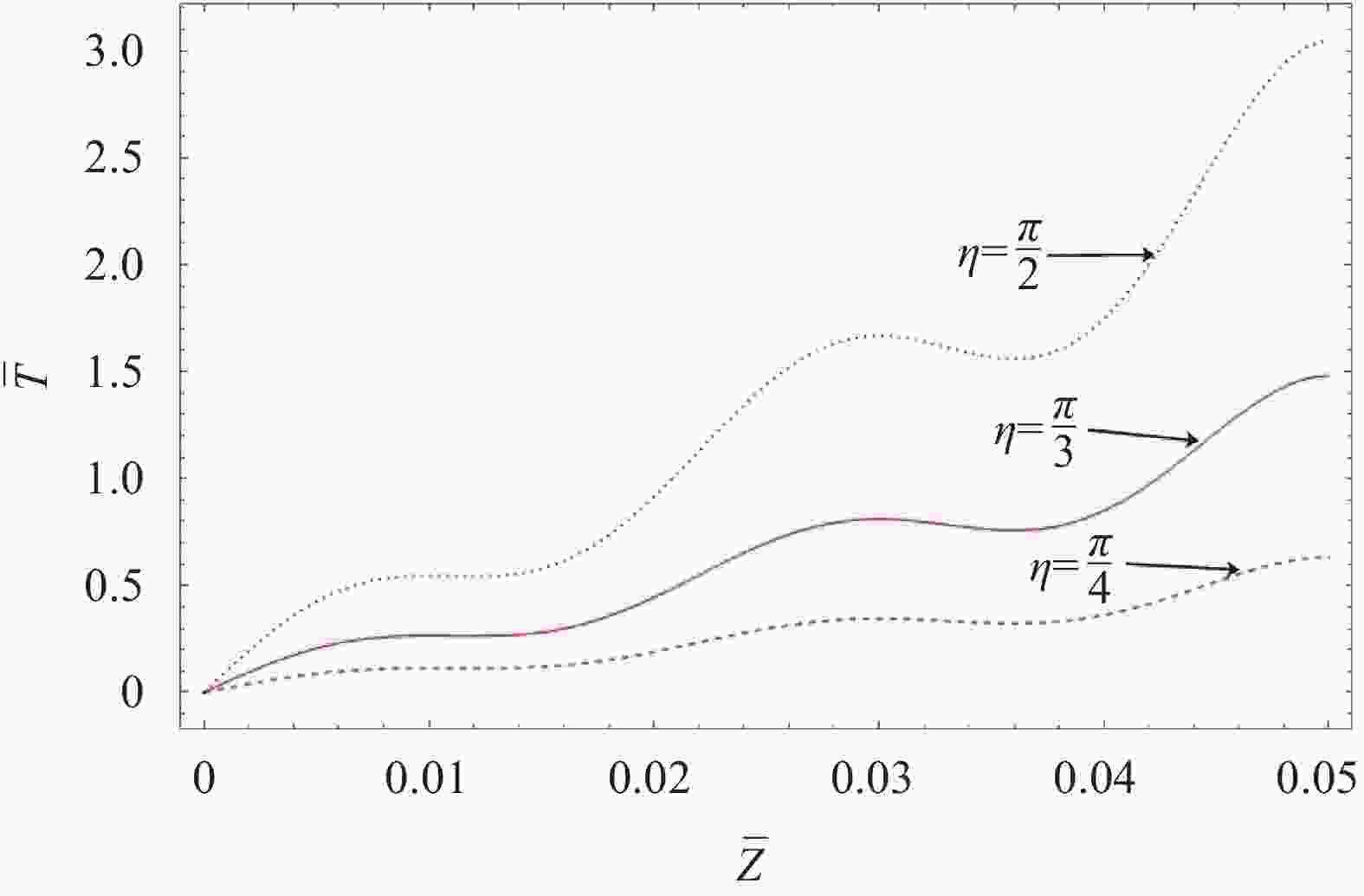

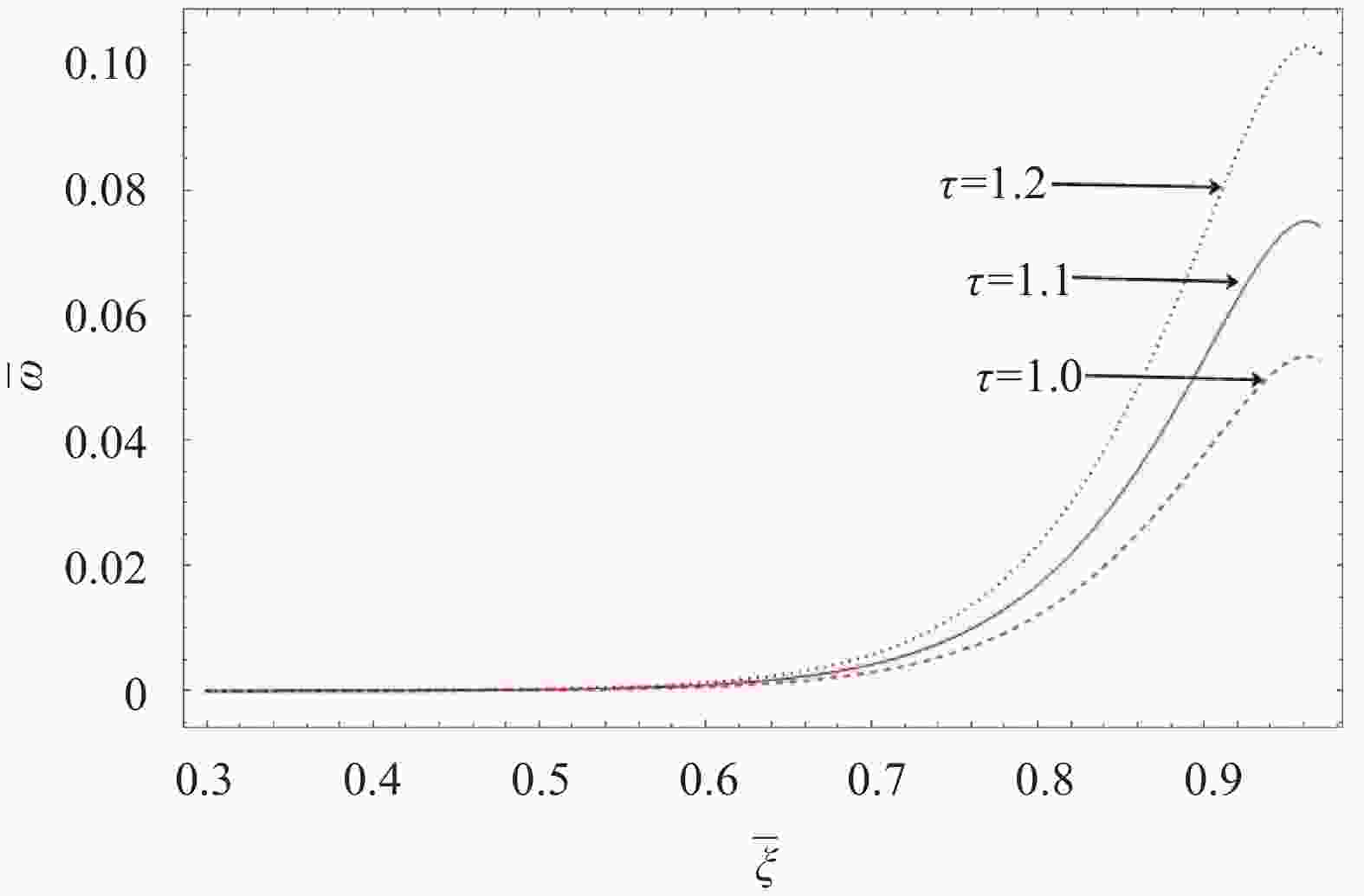

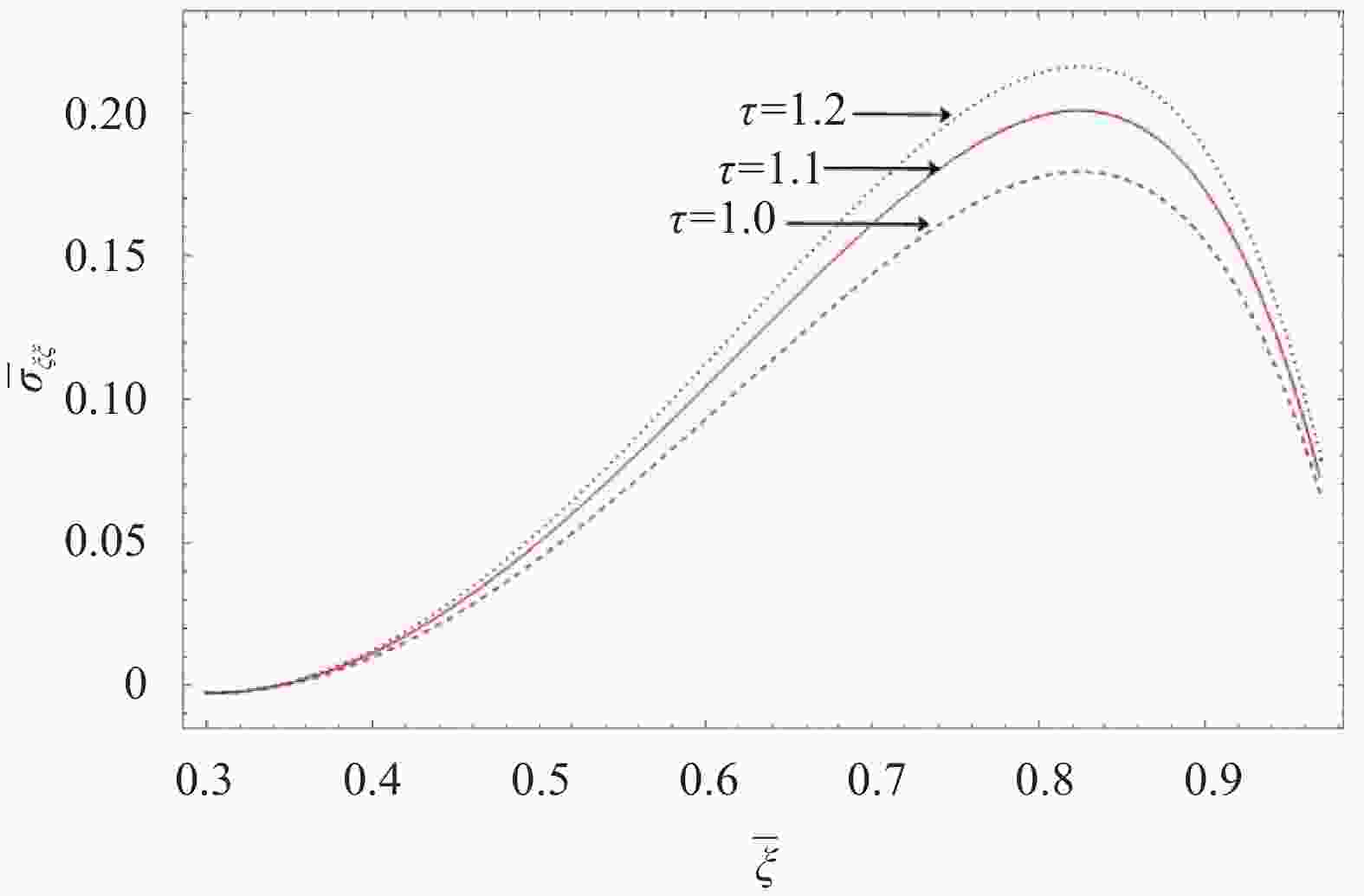

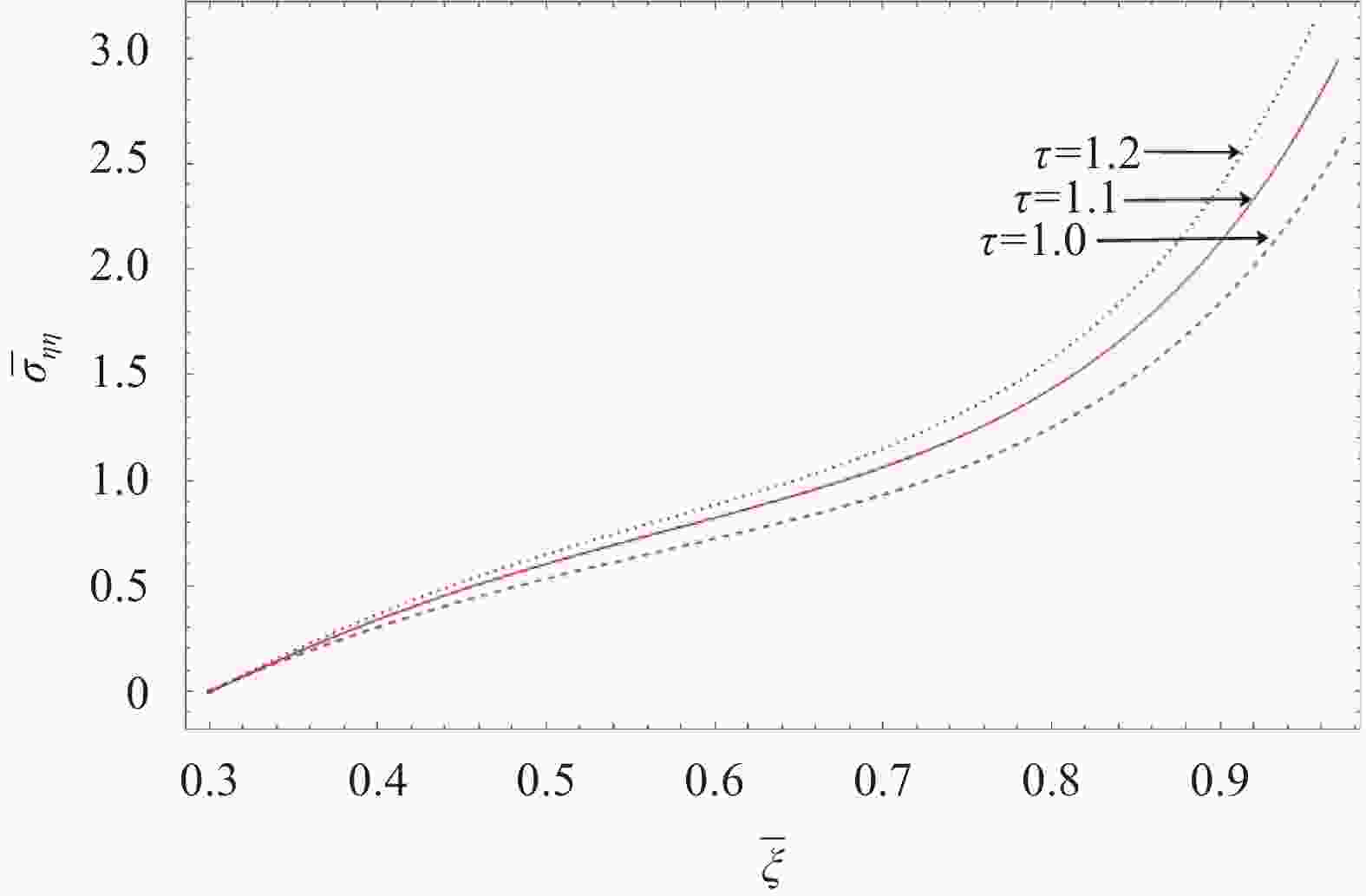

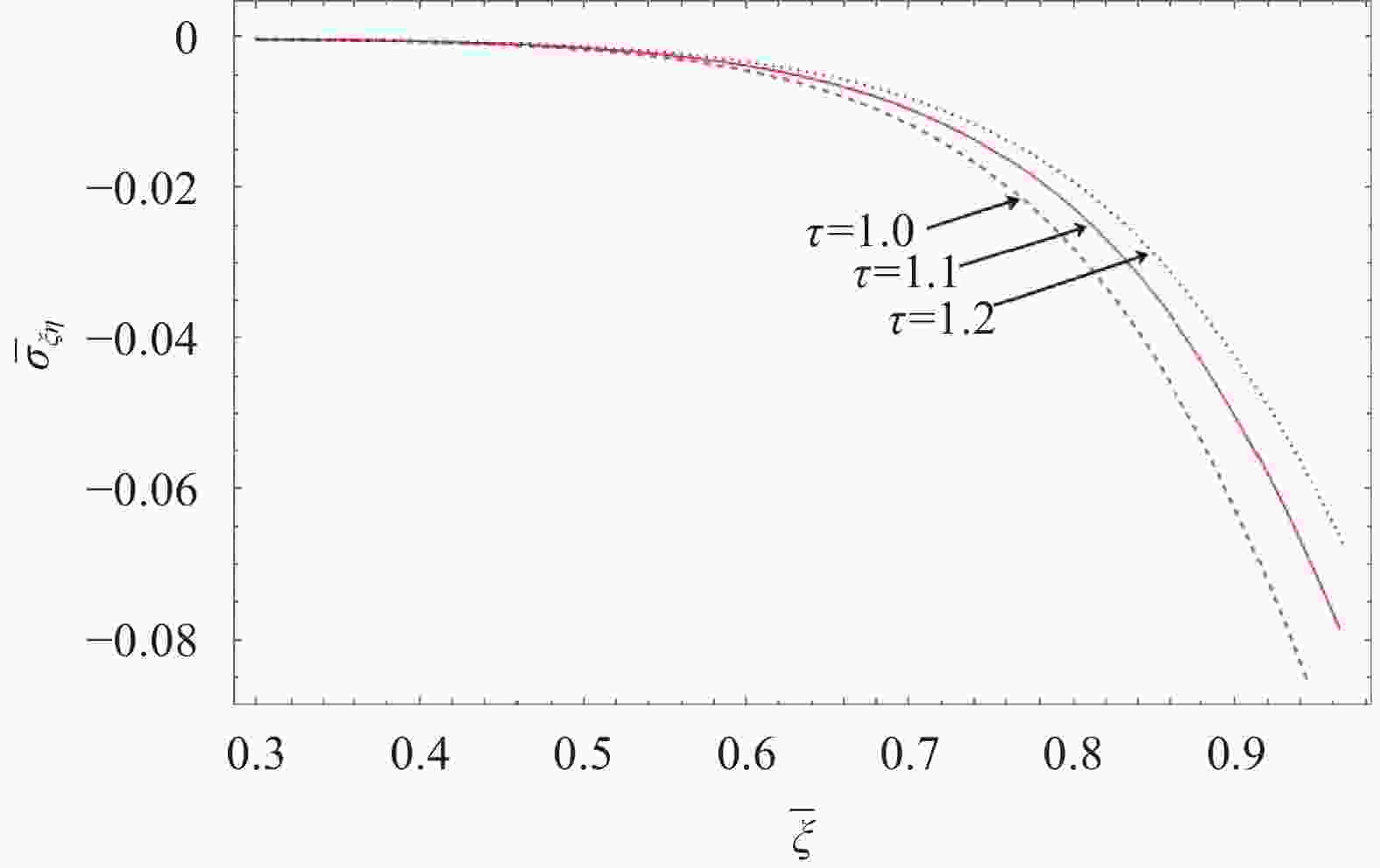

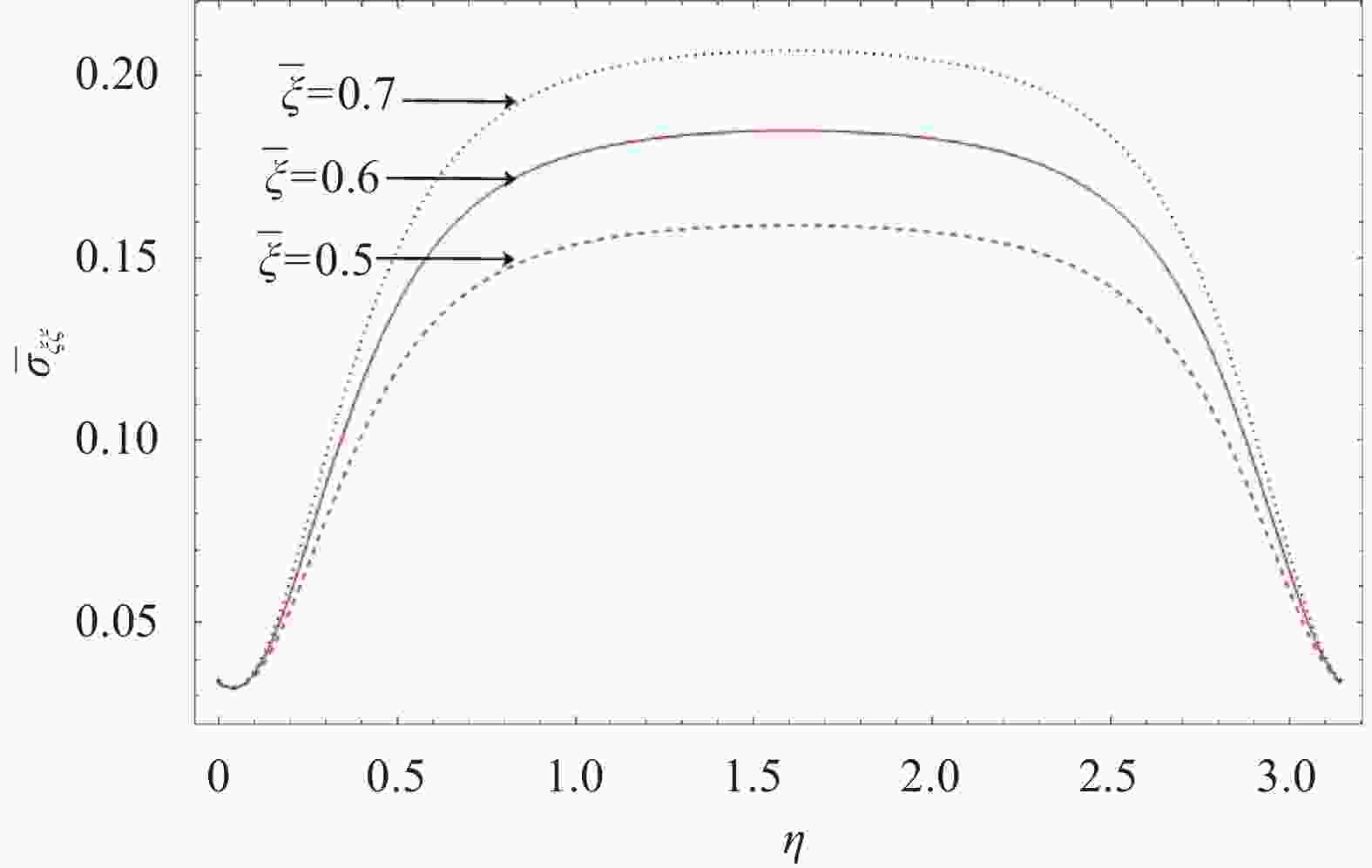

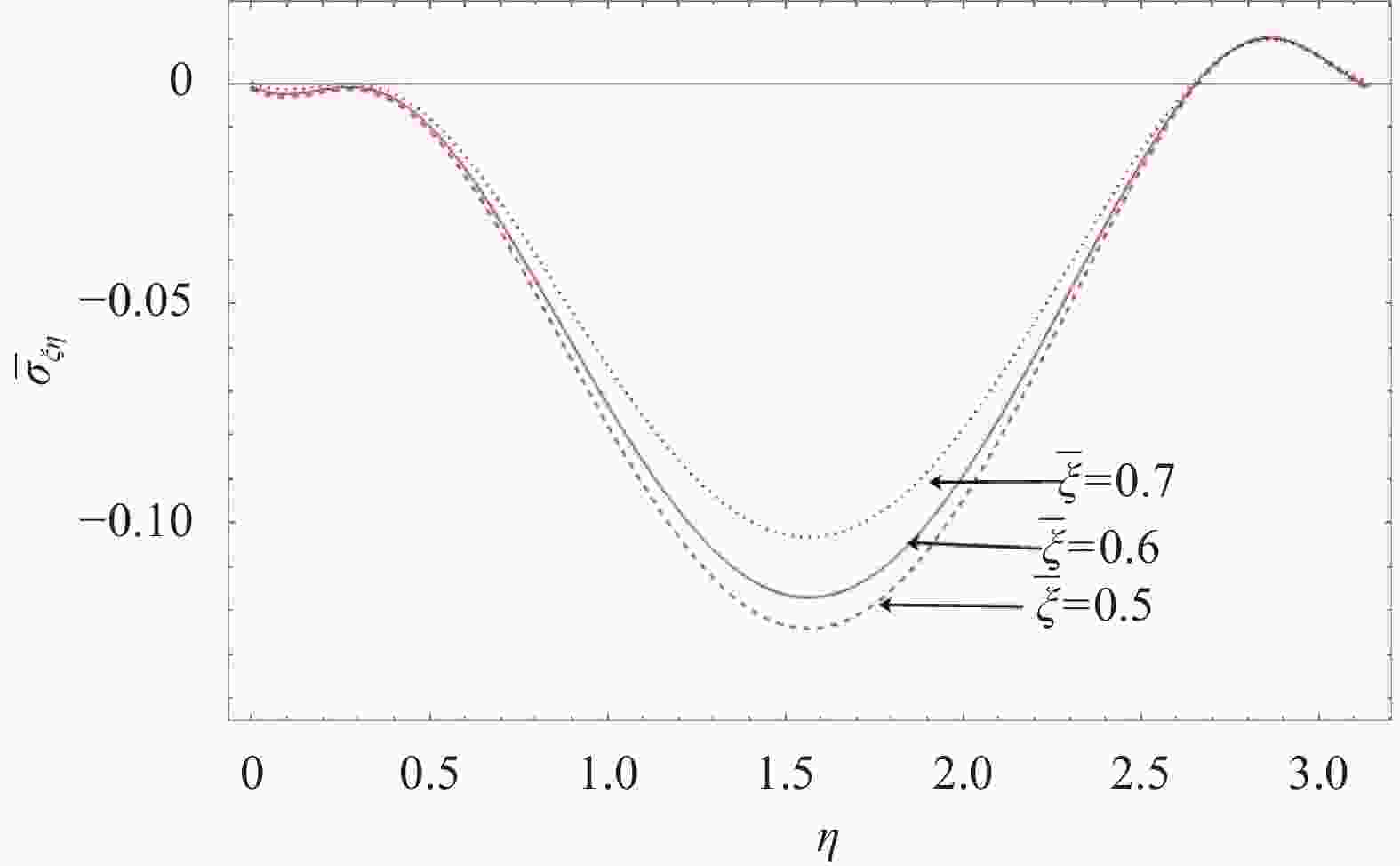

In this study, integral operational methods are used to investigate the thermally induced transverse vibration of a thin elliptic annulus plate with elastic supports at both radial boundaries. The axisymmetric temperature distribution is determined by the heat conduction differential equation and its corresponding boundary conditions by employing a unified integral transform technique by use of Mathieu functions and modified Mathieu functions. The solution of thermally induced vibration of the plate with both ends encased with elastic supports is obtained by employing an integral transform for double Laplace differential equation. The thermal moment is derived on the basis of temperature distribution, and its stresses are obtained based on resultant bending moments per unit width. The numerical calculations of the distributions of the transient temperature and its associated stress distributions are shown in the figures.

In this study, integral operational methods are used to investigate the thermally induced transverse vibration of a thin elliptic annulus plate with elastic supports at both radial boundaries. The axisymmetric temperature distribution is determined by the heat conduction differential equation and its corresponding boundary conditions by employing a unified integral transform technique by use of Mathieu functions and modified Mathieu functions. The solution of thermally induced vibration of the plate with both ends encased with elastic supports is obtained by employing an integral transform for double Laplace differential equation. The thermal moment is derived on the basis of temperature distribution, and its stresses are obtained based on resultant bending moments per unit width. The numerical calculations of the distributions of the transient temperature and its associated stress distributions are shown in the figures.

Theoretical and Applied Mechanics Letters 2018, 8(1): 43-47.

doi: 10.1016/j.taml.2018.01.001

Abstract:

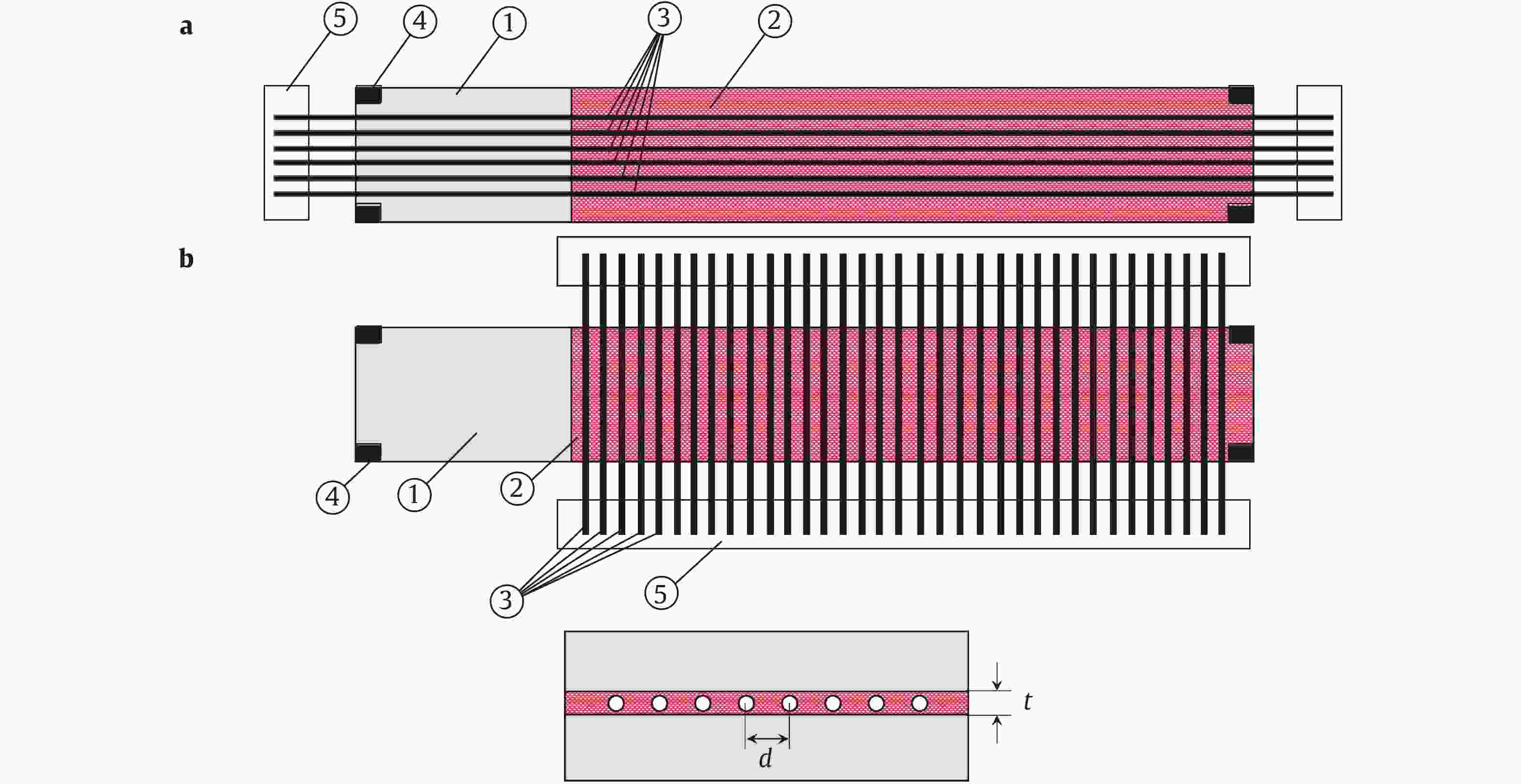

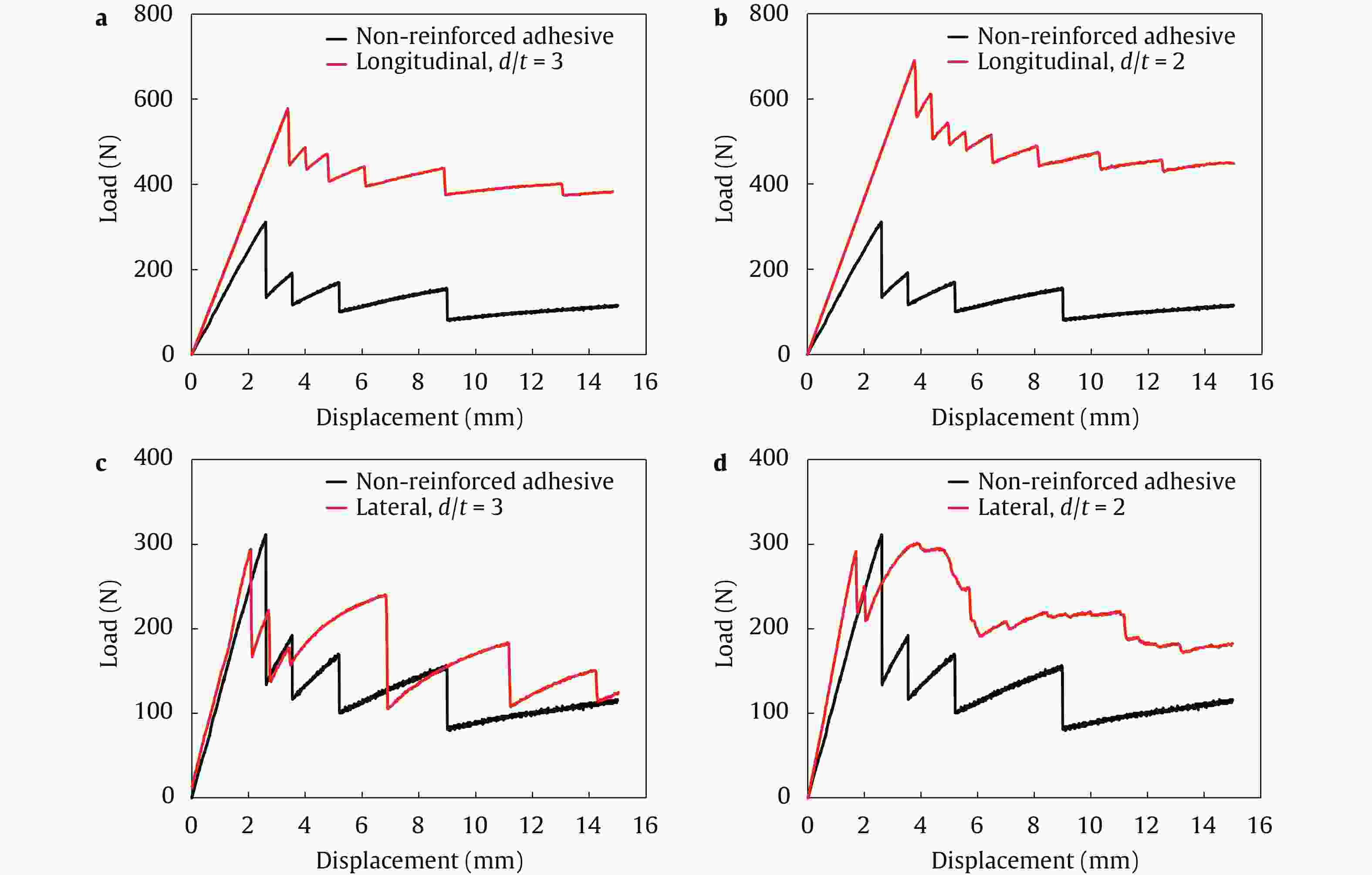

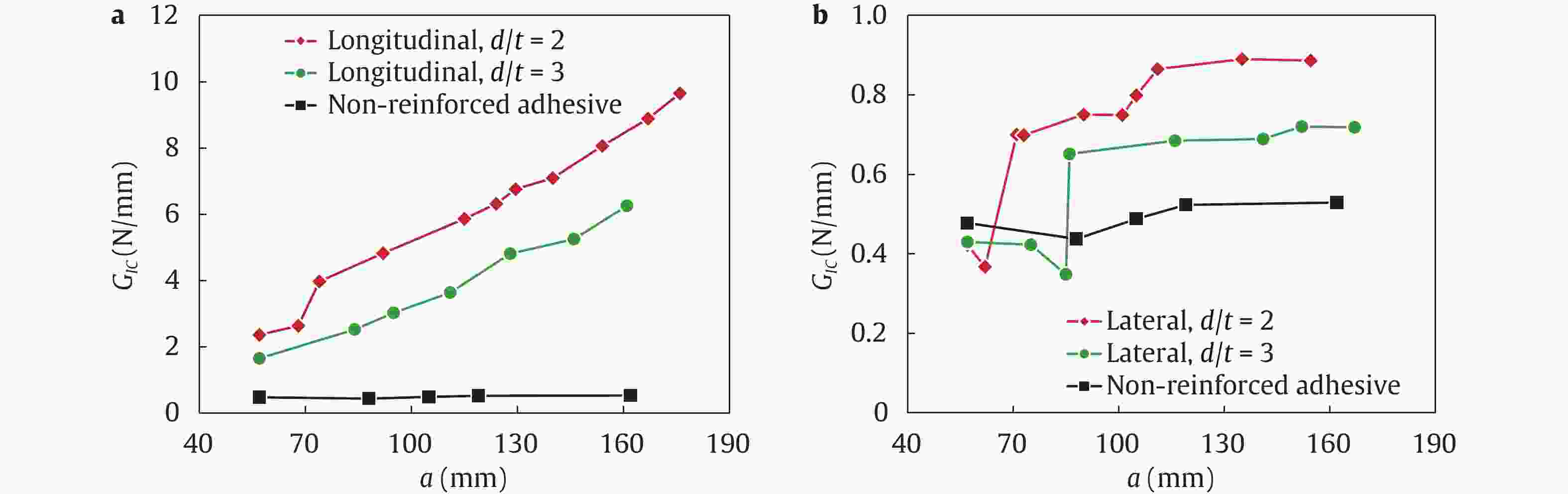

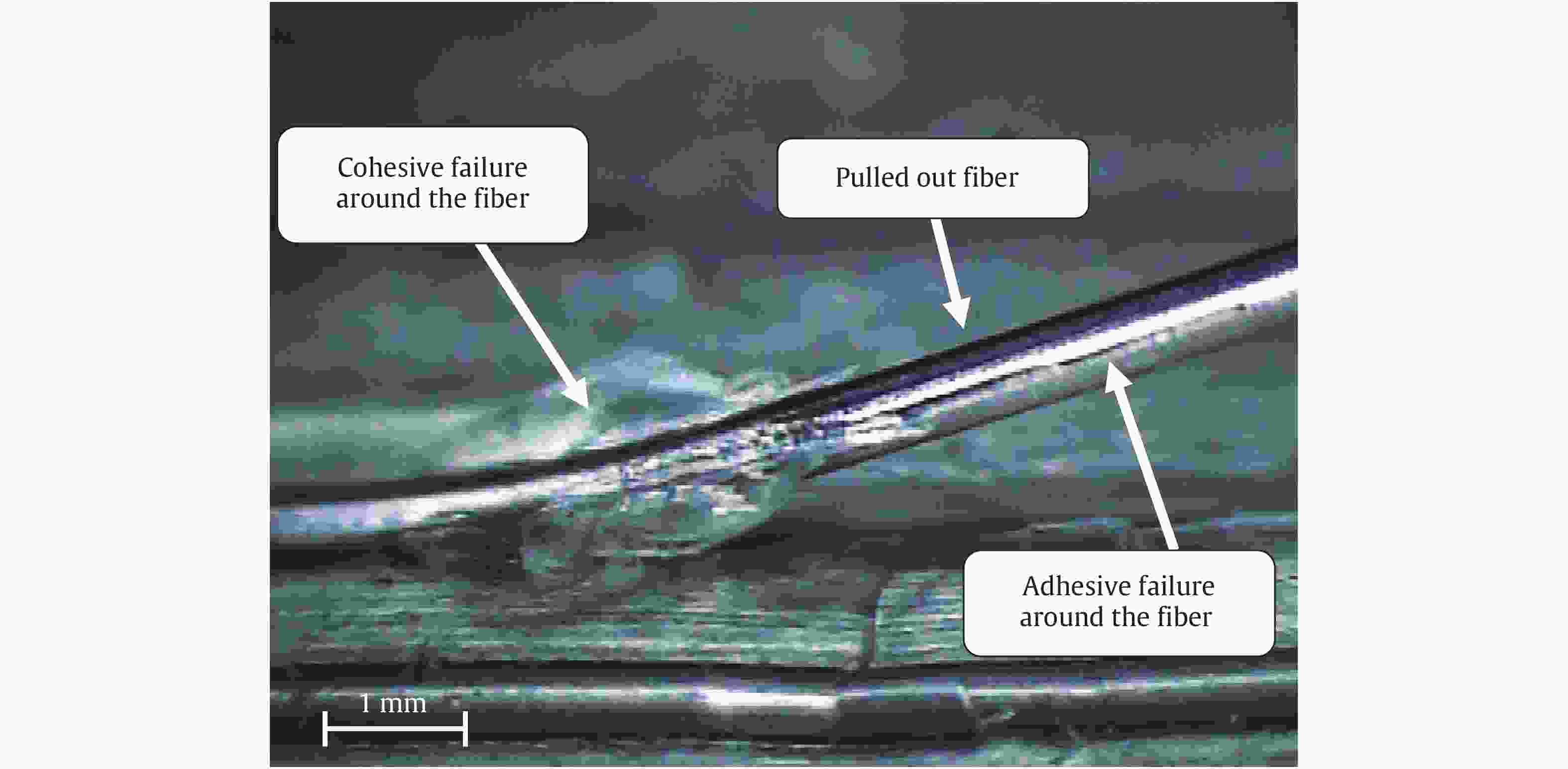

Incorporation of metallic fibers into the adhesive layer can significantly improve the mechanical behavior of the adhesive joint. This paper aims to assess the fracture behavior of an epoxy adhesive reinforced by longitudinal and lateral metallic fibers. Double cantilever beam (DCB) specimens were used to obtain the fracture energy of both non-reinforced and reinforced adhesives under mode I loading condition. In addition to the fiber orientation, the distance between the metal fibers was considered as the second key parameter in the experiments. It was concluded that although incorporation of metallic fibers in the adhesive layer improves the fracture behavior of neat adhesive, however, higher improvements were observed for the adhesive reinforced with longitudinal fibers. Furthermore, reducing the fiber distances resulted in higher values of fracture energy.

Incorporation of metallic fibers into the adhesive layer can significantly improve the mechanical behavior of the adhesive joint. This paper aims to assess the fracture behavior of an epoxy adhesive reinforced by longitudinal and lateral metallic fibers. Double cantilever beam (DCB) specimens were used to obtain the fracture energy of both non-reinforced and reinforced adhesives under mode I loading condition. In addition to the fiber orientation, the distance between the metal fibers was considered as the second key parameter in the experiments. It was concluded that although incorporation of metallic fibers in the adhesive layer improves the fracture behavior of neat adhesive, however, higher improvements were observed for the adhesive reinforced with longitudinal fibers. Furthermore, reducing the fiber distances resulted in higher values of fracture energy.

Theoretical and Applied Mechanics Letters 2018, 8(1): 48-56.

doi: 10.1016/j.taml.2018.01.010

Abstract:

Despite recent progress, laminar-turbulent coexistence in transitional planar wall-bounded shear flows is still not well understood. Contrasting with the processes by which chaotic flow inside turbulent patches is sustained at the local (minimal flow unit) scale, the mechanisms controlling the obliqueness of laminar-turbulent interfaces typically observed all along the coexistence range are still mysterious. An extension of Waleffe’s approach [Waleffe, 1997] is used to show that, already at the local scale, drift flows breaking the problem’s spanwise symmetry are generated just by slightly detuning the modes involved in the self-sustainment process. This opens perspectives for theorizing the formation of laminar-turbulent patterns.

Despite recent progress, laminar-turbulent coexistence in transitional planar wall-bounded shear flows is still not well understood. Contrasting with the processes by which chaotic flow inside turbulent patches is sustained at the local (minimal flow unit) scale, the mechanisms controlling the obliqueness of laminar-turbulent interfaces typically observed all along the coexistence range are still mysterious. An extension of Waleffe’s approach [Waleffe, 1997] is used to show that, already at the local scale, drift flows breaking the problem’s spanwise symmetry are generated just by slightly detuning the modes involved in the self-sustainment process. This opens perspectives for theorizing the formation of laminar-turbulent patterns.

Theoretical and Applied Mechanics Letters 2018, 8(1): 57-61.

doi: 10.1016/j.taml.2018.01.002

Abstract:

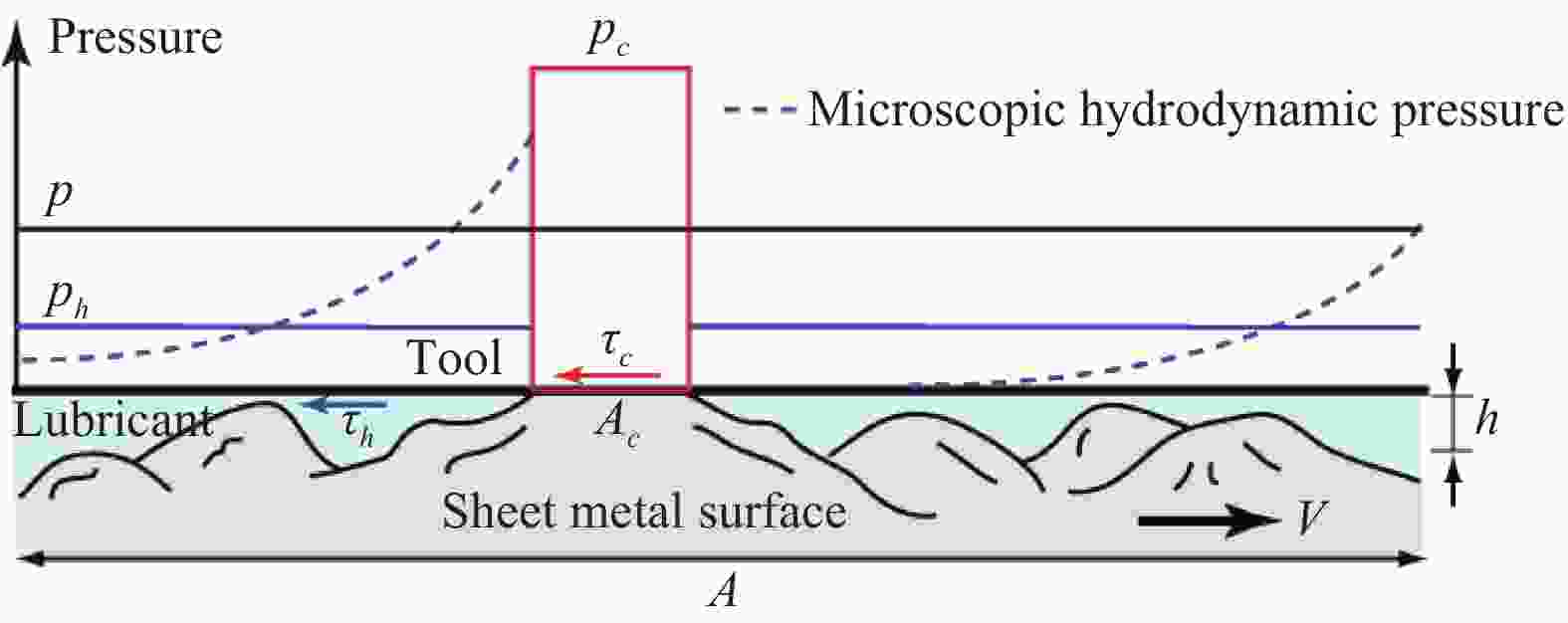

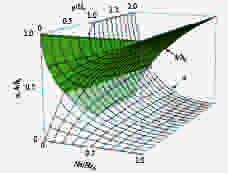

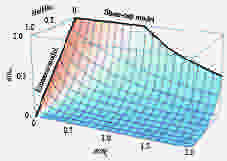

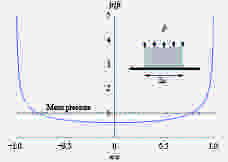

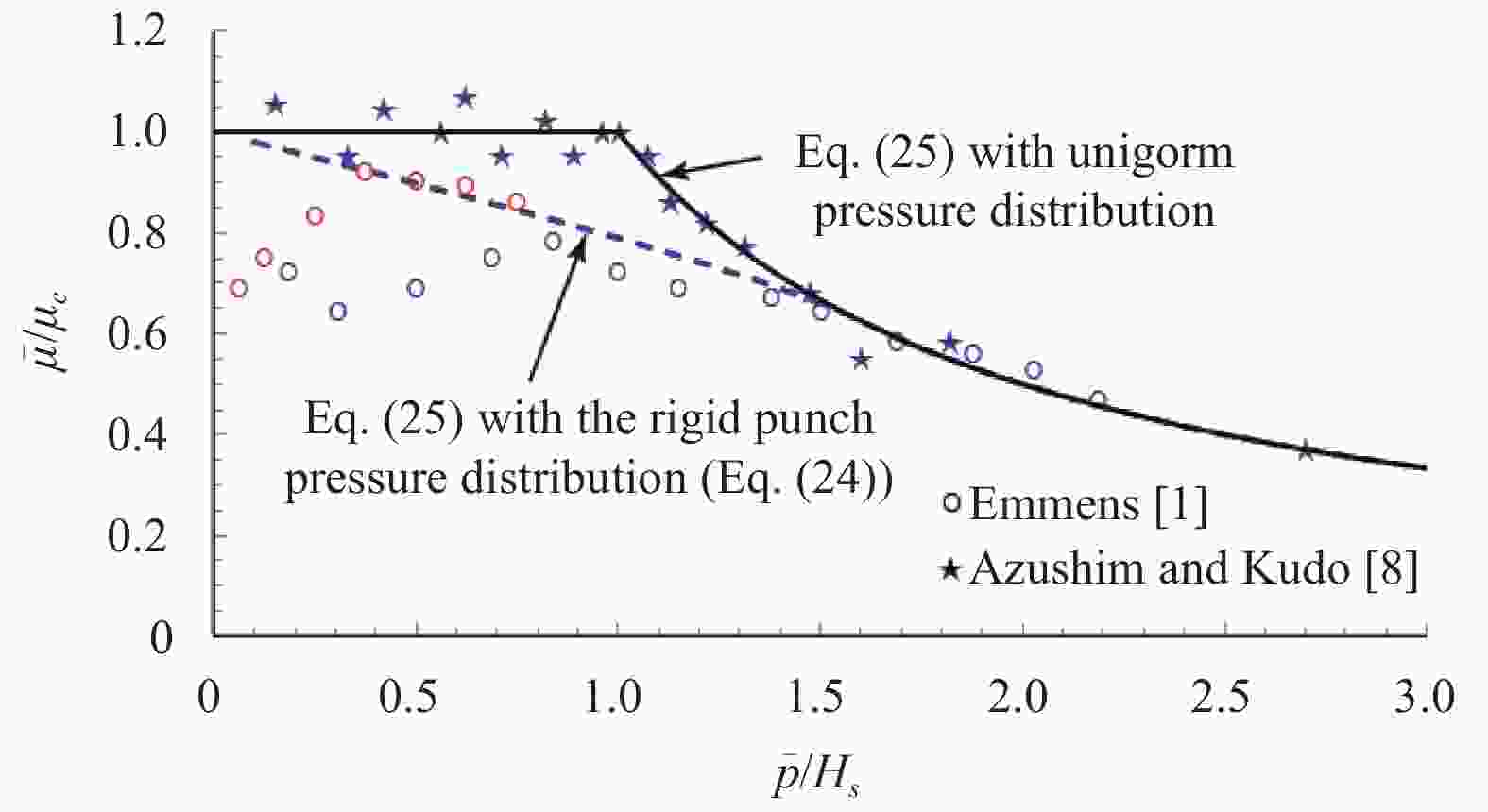

This paper presents the derivation of a first order friction model for lubricated sheet metal forming. Assuming purely plastic real contacts, Newton's law of viscosity, and a square root behavior of the hydrodynamic coefficient of friction with respect to the hydrodynamic Hersey parameter an analytic model is found. The model predicts the coefficient of friction as a function of the relative pressure, the relative Hersey parameter and the real contact coefficient of friction. Questions about local and global friction are raised in the validation of the model against flat tool sheet experiments. For some flat tool sheet experiments reasonable agreements are obtained assuming a rigid punch pressure distribution. The restricted number of user inputs makes the model useful in early tool design simulations.

This paper presents the derivation of a first order friction model for lubricated sheet metal forming. Assuming purely plastic real contacts, Newton's law of viscosity, and a square root behavior of the hydrodynamic coefficient of friction with respect to the hydrodynamic Hersey parameter an analytic model is found. The model predicts the coefficient of friction as a function of the relative pressure, the relative Hersey parameter and the real contact coefficient of friction. Questions about local and global friction are raised in the validation of the model against flat tool sheet experiments. For some flat tool sheet experiments reasonable agreements are obtained assuming a rigid punch pressure distribution. The restricted number of user inputs makes the model useful in early tool design simulations.

Submit a Paper

Submit a Paper

Subscription

Subscription

News

MORE+

Call for Papers

MORE+

- Crossing-Mechanics Driven by Big Data

- Machine learning in the fluid mechanics research of wind energy

- Mechanics of Origami/Kirigami structures and metamaterials

- New insights and perspectives on impact biomechanics for human tissues: from injury prevention, protection to protective equipment

- Environmental Mechanics for Extreme Natural Events